Discover Our Rotary Drum Mixers

Continental Products currently designs and manufactures six, distinct rotary drum mixers, known as Rollo-Mixers. We recognize that one rotary drum design is not absolutely ideal for every application. Which is why we engineer several, versatile, rotary drum batch mixers with unique capabilities and advantages across hundreds of applications. Each design has unmatched capabilities to optimize a wide variety of batch mixing, blending and coating processes. We are committed to relentlessly improving the Rollo-Mixer®, to provide exceptional operating performance for our customers and their finished products.

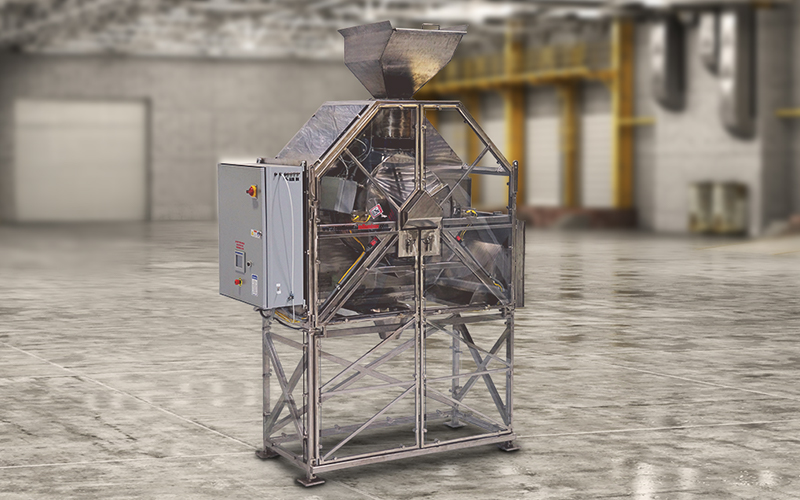

Mk VI

Features & Benefits

- Uniform Batch Mixing & Blending in under 3 minutes

- Award winning liquid addition Free-Fall Processing®

- Available in 51 sizes from 3.5 to 1,286 cu ft

Industries:

Applications

Animal Health Products, Calf Milk Replacer, Animal Feed with Molasses, Trace Mineral Pre-Mixes, Specialty Polymers, Treating Powers, Industrial Cleaners, Insulation Products, coating Kaolin Clays, Magnesium Oxide Powders, and more.

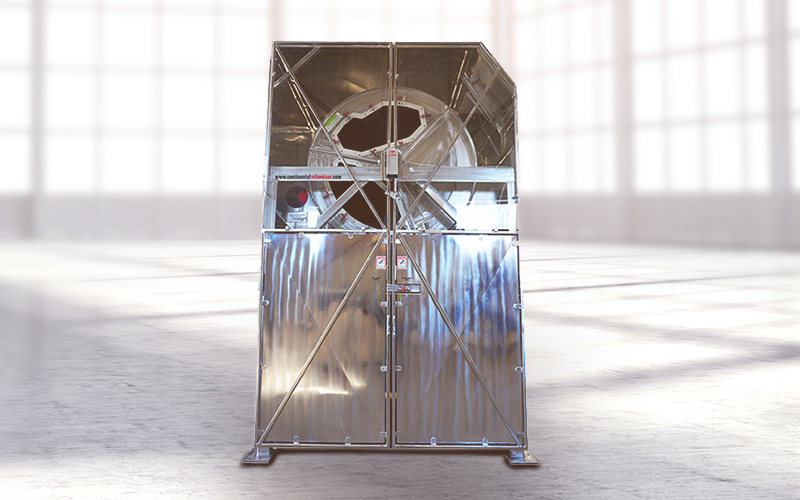

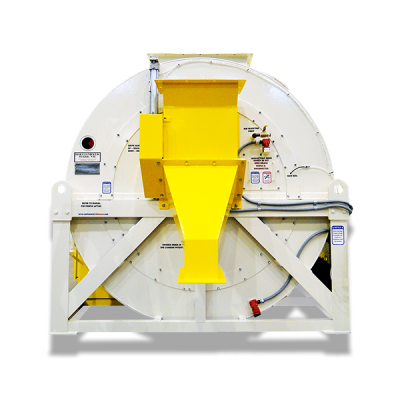

Mk VII

Features & Benefits

- Gentle, Consistent, Uniform Blending

- Homogenize Large lots in 3 minutes

- The World’s largest rotary drum mixer

- Available in 51 sizes from 3.5 to 1,286 cu ft

Industries:

Applications

Plastic Pellets, HDPE Pellets, Vinyl Composite Floor Tile Cubes, Industrial Detergents, Catalysts, Fluoropolymers, Plastic Additives, Specialty Compounds, Granular Ag Chemicals, and more.

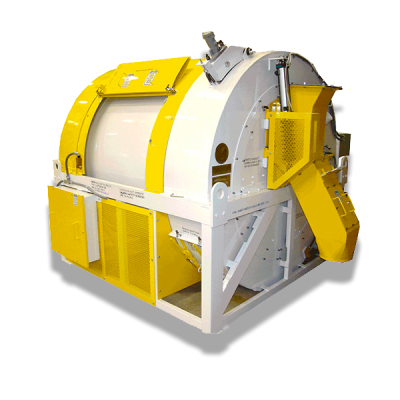

Mk VII-1

Features & Benefits

- Uniform Mixing and Blending in under 3 minutes

- Precise liquid addition – featuring Free-Fall Processing®

- Versatile Solids Processor – available with heating & cooling capabilities.

- Available in in 51 sizes from 3.5 to 1,286 cu ft

Industries:

Applications

Animal health products, calf milk replacer, animal feed with

molasses, trace mineral pre-mixes, specialty polymers, treating powders, industrial cleaners, insulation products, coating kaolin clays, magnesium oxide powders and much more.

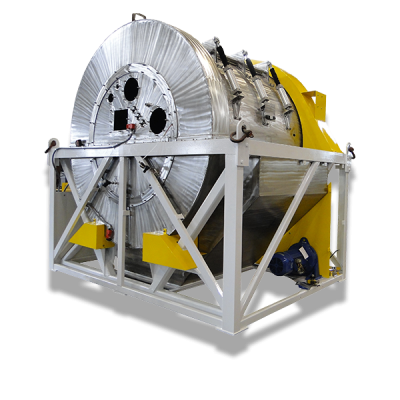

Mk VIII

Features & Benefits

- High Purity Uniform Mixing in minutes

- Rinse, Clean & Dry in under 15 minutes

- Superior Uniformity & Cleanout to Vee & Cone Blenders

- Available in 9 sizes, from 3.5 to 400 cu ft.

Industries:

Applications

Nutritional powders, nutraceuticals, dietary supplements, powdered drink mixes, supplement powders, and other food grade powders. Also, metal powders, plastic piping & tubing and refractory ceramic powders.

Mk IX

Features & Benefits

- Premier Batch Coater for Slow release fertilizers

- Ability to Heat / Coat & Cool Various Substrates

- Pilot & Production Coaters Available

- Batch to Batch Reproducibility

- Available in 10 sizes, from 3.9 to 297 cu ft

Industries:

Applications

Controlled release fertilizers, polymer coated fertilizers, biological growth enhancers, micro-layering EPS spheres, agricultural chemicals, pest control products, larvicide and other substrates to be coated with difficult-to-spray liquids.

Mk X

Features & Benefits

- Extremely Gentle, Food Grade Blending

- Uniformity in 80 seconds

- Used for friable snack, nuts and fruit blends

- Rinse, Clean & Dry in under 12 minutes

- Available in 11 sizes from 5 to 386 cu ft

Industries:

Applications

Mixing snacks and nuts, snack mixes, frozen or dehydrated fruits, vegetable and more.

History Timeline

1959 – Mark I

Original Concept

1960 – Mark II

- Designed to mix wet animal feeds with liquid molasses.

- Three models available in 3, 5 and 7 ton capacities.

1961 – Mark III

- Designed to mix wet or dry feed and grains with molasses, minerals, trace additives, and antibiotics.

- Eight models available in 2 through 10 ton capacities.

- Many are still in use today

1965 – Mark IV

- Designed to mix dry chemicals with liquid additives.

- Ten models available in 1 through 10 ton capacities.

- Many are still in use today

1968 – Mark V

- Designed to continuously turn, fold and cross mix any batch of dry particulate matter, with or without liquid additives, to a uniform blend.

- Over 70 models available in models available in 10 to 10,000 cu ft load volume capacities.

- Unmatched mixing accuracy – test proven

- Unique “free fall impregnation” of liquid additives.

1992 – Mark VI

The Mk VI is well known for blending fine powders and dry articulates, for a variety of applications that demand consistent uniformity. Mk VI data shows industry leading results for many applications.

- Unmatched Blending Accuracy

- Featuring Free-Fall Processing

- Batch to Batch consistency

- Updated seal design

1994 – Mark VII

The Mk VII is a drum blender designed for gentle/uniform mixing and blending applications with pellets, granules and powders used in many large scale plastics and petrochemical applications.

- Designed for uniform Gentle Blending

- Free-Fall Processing with multiple falling curtains

- Enclosed turbine design

- Advanced seal design

1998 – Mark VII-1

The Mk VII-1 is a versatile rotary drum mixer designed for uniform mixing, blending and coating of powders, pellets and granules having a wide variance in particle size and density in minutes.

- Mixing & Blending Consistency

- Free-Fall Processing

- Versatile solids processor

- Advanced cleanout options

2002 – Mark VIII

The Mk VIII Rollo-Mixer® is a dry blender designed for uniformly blending dry food grade powders vitamins, nutraceuticals, sports drink powders and dietary supplement powders.

- Designed for high purity dry blending

- No mechanical drum seal

- Consistent uniformity

- Superior cleanout and wash-down capability

2008 – Mark IX

The Mk IX Rollo-Mixer® Batch Coater was originally designed to evenly spray two-part polymer epoxies, resin and hardeners onto a wide range of substrates

- Designed for batch coating applications

- Cutting edge coating technology

- Pilot and production batch coaters

2014 – Mark X

The Mk X Rollo-Mixer® is a food grade industrial blender for snacks, designed for extremely gentle batch mixing of very friable dry snack food ingredients.

- Designed for snack blends, nuts and fruits

- Extremely gentle food grade blending

- Uniformity in 80 seconds

What Our Customers Are Saying

“It coats evenly, it’s smooth, it’s low impact, it works the best of any other style batch mixers we have used”

“Free-Fall Processing® gives us the finesse needed to apply liquids with precision, making our product #1 on the market today.”

“Rollo-Mixers give us the best in Uniform Blending and Precise Liquid Addition on our powders”

“The Rollo-Mixer gives us the best results of any rotary drum mixer we have used”

“ We blend 25,000 lbs uniformly in 3 minutes with no re-work.”

“We sell quality and uniformity. Better than our competition, because of the Mk VII Rollo!”

“We have not had a batch off spec since we put the Rollo-Mixers on line in 1998. Incredible, since we run 24/7/365 and make over 1 million lbs per day in them.

Call Us Directly to Find the Right Rollo Mixer for your Application

Test Your Product

We invite you to run trials with a 5 or 10 cu ft Rollo-Mixer® and take samples with your Products at our facility in Wisconsin. Discover our innovative Free-Fall Processing® feature as well as other unique components that make Rollo-Mixers an optimal choice for many applications and industries

Tell Me MoreCall Us Directly

Call us now to discuss your application. We have worked directly with our customers for over 50 years and are happy to lend our trusted knowledge to your application. We’re here to help you directly from your initial interest and testing to start up and for the lifespan of your Rollo-Mixer®.

Contact Us