High Purity Dry Blending in Rollo-Mixers

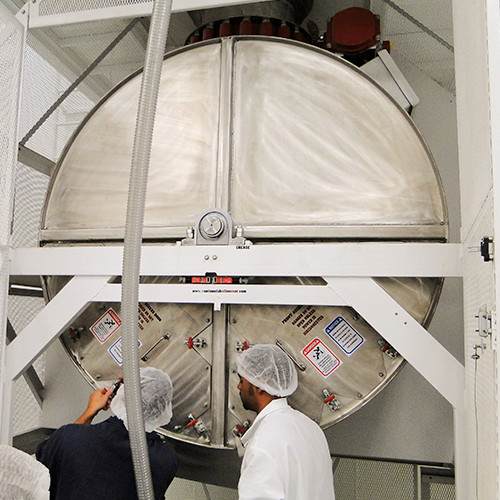

The Mk VIII and Mk X Rollo-Mixers are ideal for high purity dry blending and food grade batch mixing applications, where cleanout and easy access are critical for quick product change over between batches. It is an excellent alternative for these industries who typically use ribbon mixers, paddles, V-Blenders and Cone Blenders. Rollo-Mixer’s used in food grade applications are built with our food grade package. This is in line with GMP standards and uses components such as; 150 grit polished stainless steel, wash down motors, lube fee chains, food grade gasketing, and nickel plated bearings and tank washing nozzle assemblies for C.I.P.

Recommended Rollo-Mixers ® for High Purity Dry Blending

Mk VII

Features & Benefits

- Gentle, Consistent, Uniform Blending

- Homogenize Large lots in 3 minutes

- The World’s largest rotary drum mixer

- Available in 51 sizes from 3.5 to 1,286 cu ft

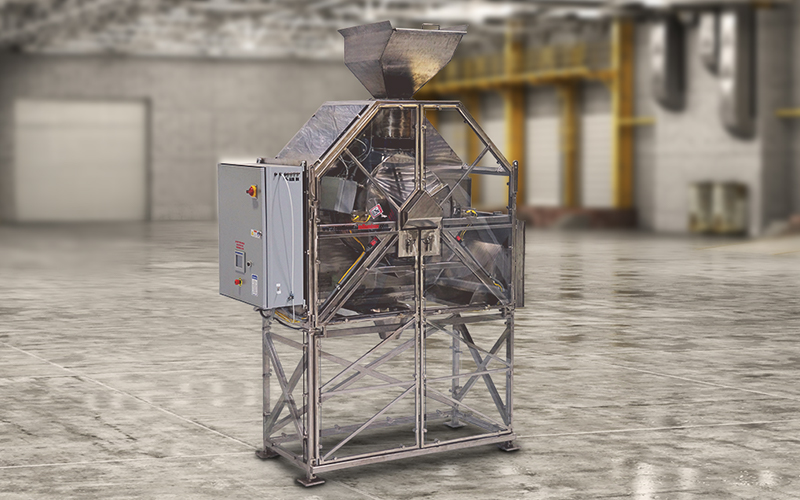

Mk VIII

Features & Benefits

- High Purity Uniform Mixing in minutes

- Rinse, Clean & Dry in under 15 minutes

- Superior Uniformity & Cleanout to Vee & Cone Blenders

- Available in 9 sizes, from 3.5 to 400 cu ft.

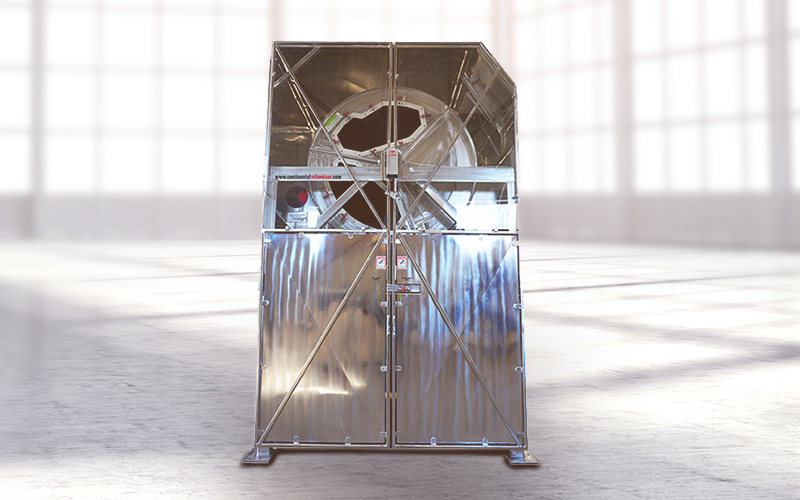

Mk X

Features & Benefits

- Extremely Gentle, Food Grade Blending

- Uniformity in 80 seconds

- Used for friable snack, nuts and fruit blends

- Rinse, Clean & Dry in under 12 minutes

- Available in 11 sizes from 5 to 386 cu ft

A World Leader in Rotary Drum Mixing, Blending, and Coating Technology

We’ve been leading the way in innovative solutions for mixing, blending and coating since 1960. Take Advantage of the substantial benefits available to you through our years of experience.

Substantial Raw Material Savings

Simplify Entire Process

Major Electrical Savings and Rebates

Eliminate Rework

Improve Quality of Finished Products

Increase Production

Test Your Product

We invite you to run trials with a 5 or 10 cu ft Rollo-Mixer® at our facility in Wisconsin. Continental will create a private video of the test, exclusively for your review. Viewing windows allow you to watch the blend, and microscope pictures showcase the Rollo-Mixer’s effectiveness. See your high purity products uniformly blended in the Rollo-Mixer®

Tell Me MoreCall Us Directly

Call us now to discuss your application. We have worked directly with our customers for over 50 years, and are happy to lend our trusted knowledge to your application. We’re here to help you directly from your initial interest, and testing…. to start up and for the lifespan of your Rollo-Mixer®

Contact Us