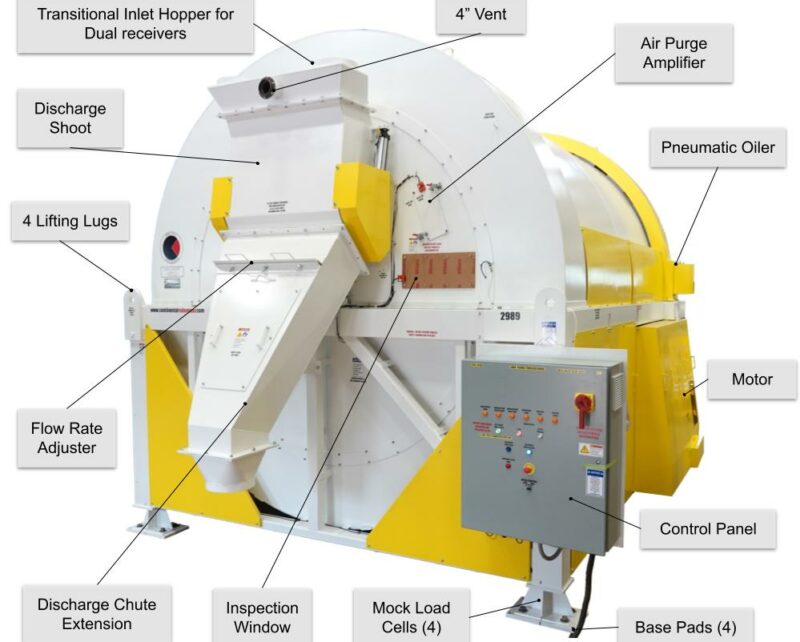

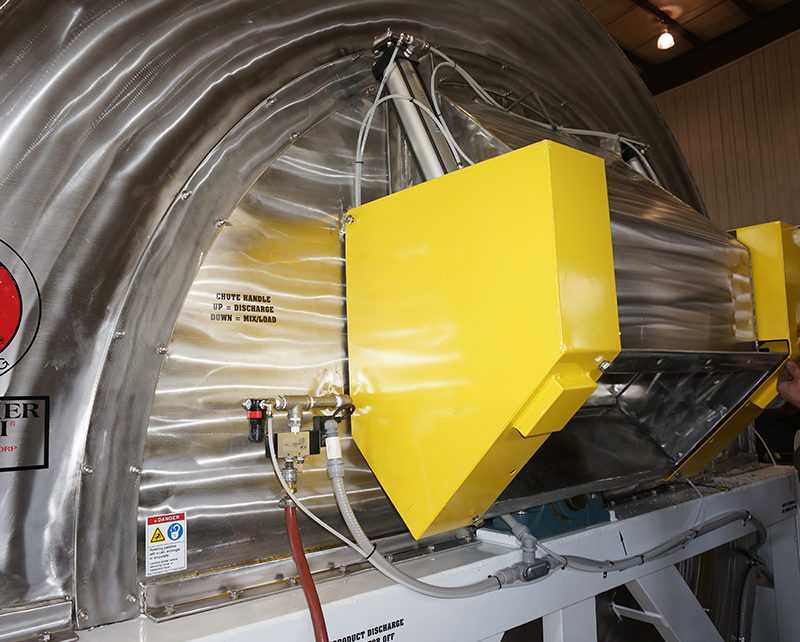

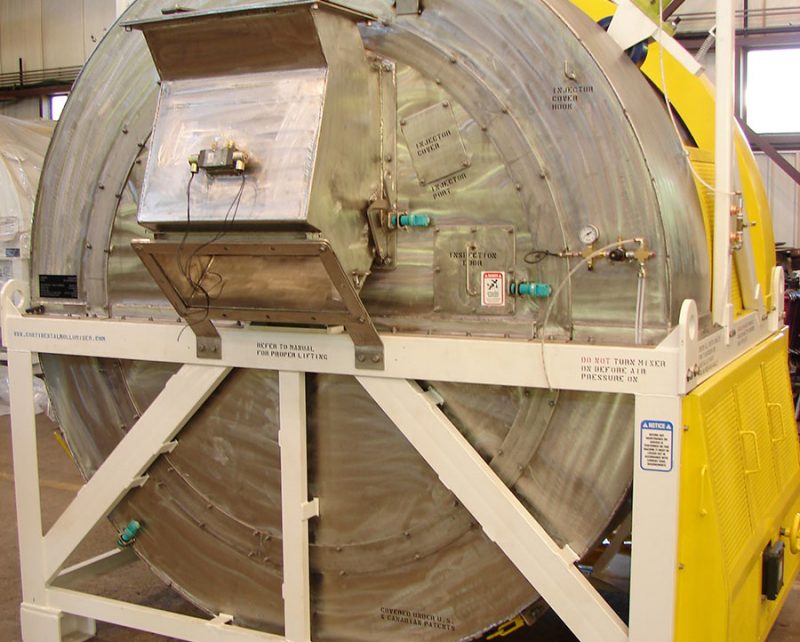

Mk VII Rollo-Mixer® Drum Blender

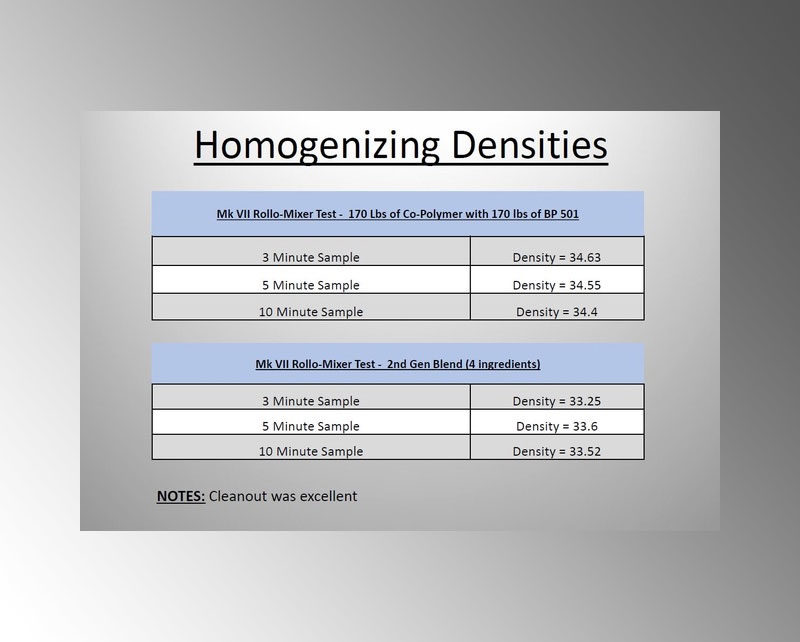

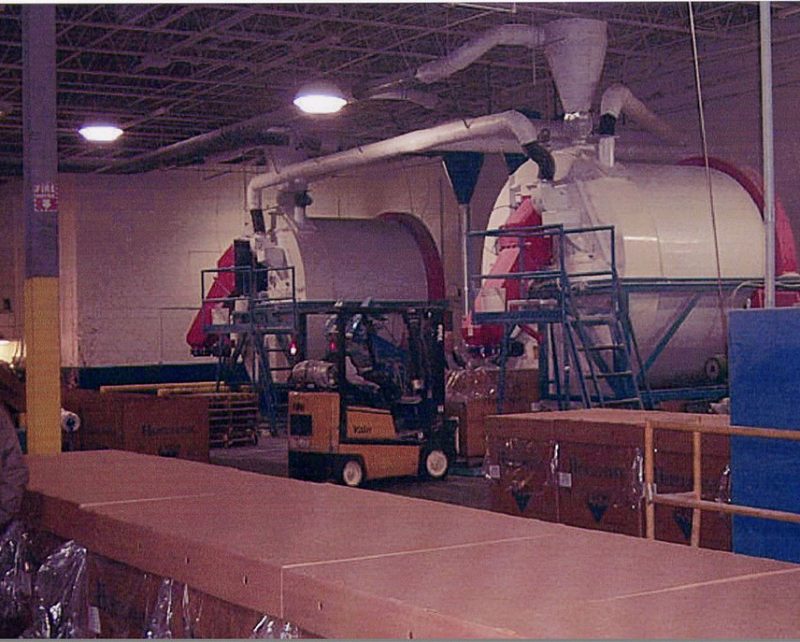

The Mk VII is a drum blender designed for gentle/uniform mixing and blending applications with pellets, granules and powders used in many large scale plastics and petrochemical applications for gentle batch blending consistency. An enclosed turbine section allows for larger particles and pellets to flow unimpeded. The largest Mk VII made has 1,286 cu ft of working load volume and blends 65,000 lbs in 3 minutes uniformly.

The Mk VII design is ideal for: plastic pellets, HDPE pellets, vinyl composite floor tile cubes, industrial detergents, catalysts, fluoropolymers, plastic additives, specialty compounds, granular ag chem products, and others.

- Mk VII Photos & Videos

- Gentle, consistent, uniform blending

- Homogenize large lots in under 3 minutes

- The Mk VII is the world’s largest rotary drum mixer

- Features Free-Fall Processing®

- Complete discharge

- Available in 51 sizes from 3.5 to 1,286 cu ft

- Mk VII Features & Accessories

Mk VII - Media Gallery

Mk VII - Features & Accessories

Loading

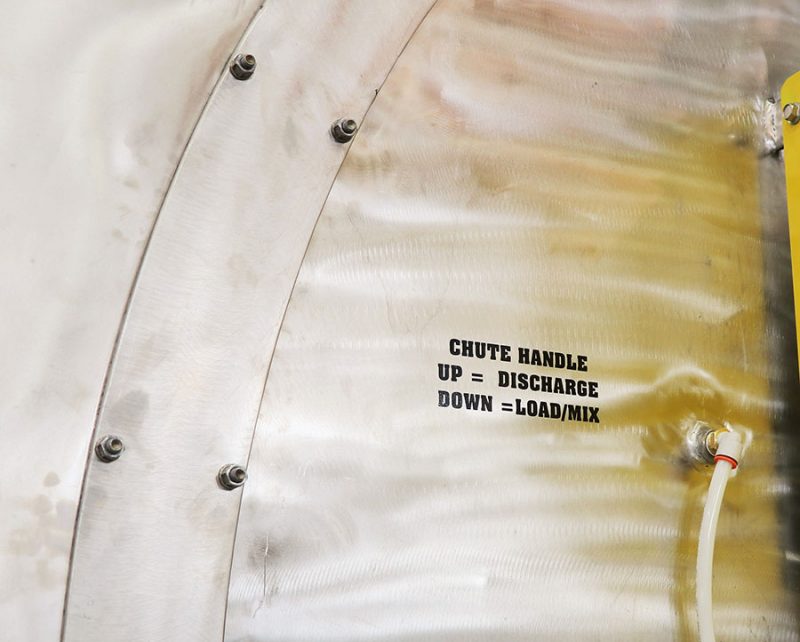

The Mk VII can be loaded through the top of the large discharge chute, from hoppers above or pneumatic transporters. This bulk blending equipment is full at shaft center. Multiple ingredients can be loaded by gravity from: silos, super saks, Gaylord bags or pneumatically, while the machine is at rest or in motion.

Discharge

Uniformly blended material from multiple free-falling curtains are diverted out the large discharge chute in a steady, unimpeded, uniform stream. Mk VII discharge chutes are larger than our other drum blending equipment. Depending on the speed and size of the mixer, product can be discharged at a faster rate than a Mk VI or VII-1. The Mk VII continues running until product discharge is complete.

Testimonials

“Best plastic pellet blender on the market today.”

“ We blend 25,000 lbs uniformly in 3 minutes with no re-work.”

“We sell quality and uniformity. Better than our competition, because of the Mk VII Rollo!”

Additional Information

Materials of Construction Finishes Available

(material contact points)

- Carbon Steel – High Release Finish

- 304 L Stainless Steel

- 80 or 150 grit Polished finish

- Abrasion Resistant Plate

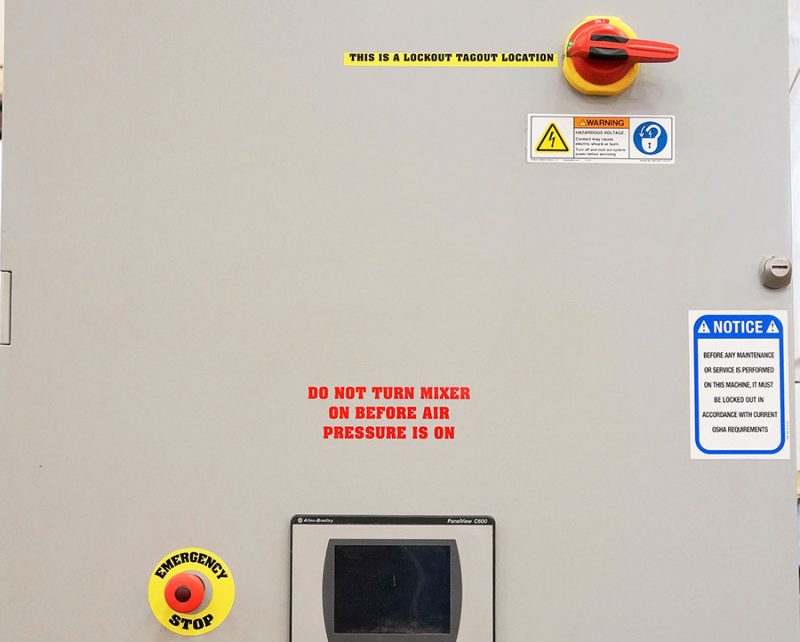

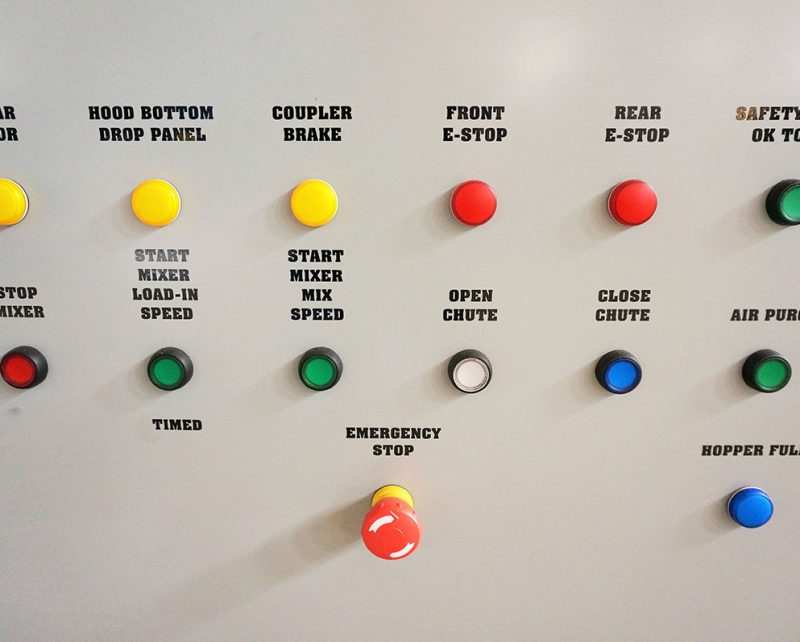

Safety & Maintenance

- State of the art safety switches

- Painted Carbon or Stainless Steel Guarding

- Accessible Zirk fittings

- Automatic chain oiler

Standards

- CE

- CSA

- NEMA 12,

- NEMA 4x

- Class II, Div. 1 & 2

Mk VII Series & Sizes

Mk VII Series & Sizes – Available in 51 sizes from 3.5 to 1,286 cu ft Contact us for dimensional specifications.

- 28 Series (3.5 ft³, 5 ft)

- 31 Series (10 ft³, 15 ft³)

- 50 Series (25 ft³ – 40 ft³)

- 62 Series (40 ft³ – 83 ft³)

- 74 Series (75 ft³ – 172 ft³)

- 86 Series (133 ft³ – 267 ft³)

- 98 Series (200 ft³ – 400 ft³)

- 101 Series (343 ft³ – 629 ft³)

- 120 Series (533 ft³ – 1000 ft³)

- 132 Series (833 ft³ – 1286 ft³)

Load Volume Calculator

Test Your Product

We invite you to our test facility in Wisconsin to run trials with the 5 or 10 cu ft Mk VII Rollo-Mixers®. Watch your products be uniformly blended, or treated with liquids in multiple ways exclusively through “Free-Fall Processing”®

Tell Me MoreContact Us Directly

Call us now to discuss your application. We have worked directly with our customers for over 50 years, and are happy to lend our trusted knowledge to your application. We’re here to help you directly from your initial interest, and testing…. to start up and for the lifespan of your Rollo-Mixer®

Contact Us