The Petrochemical Industry

The petrochemical industry has many needs for the gentle, precision uniformity that different models of Rollo-Mixers provide. Fortune 100 companies use the Mk VII as an industrial mixer for catalysts used in tube reactors, including one application where 65,000 lbs are blended in 3 minutes. The Mk VIII is used to blend metal powders at over 300 lbs per cu ft which are used in blasting caps for seismic acquisition with an explosive source to achieve consistent timing of detonation. Explosive charges are used to perforate wells in preparation for production of natural gas and oil. Many drilling fluid polymer powders and various supporting products are also blended/coated in Rollo-Mixers. Dry liquid compounds made in Mk VII-1 Rollo-Mixers are used making calcium inhibitors which prevent corrosion in gas and oil pipes. The Mk IX batch coater is used to coat different sized buoyant spheres which line the jackets in drill riser buoyancy modules.

Request More InformationPetrochemical Applications

Petrochemical Samples made with Rollo-Mixers®

The Petrochemical samples seen here represent some of the extremes for Rollo-Mixers. Powdered metals may be the heaviest blend yet at over 300 lbs per cu ft; one of the largest chemical companies bought the largest Rollo-Mixer ever made at 1,286 cu ft for mixing catalysts uniformly to cool reactors. And coating buoyancy spheres which are made with a completely automated system for powder feeding, liquid coating, heating and cooling.

View More Samples

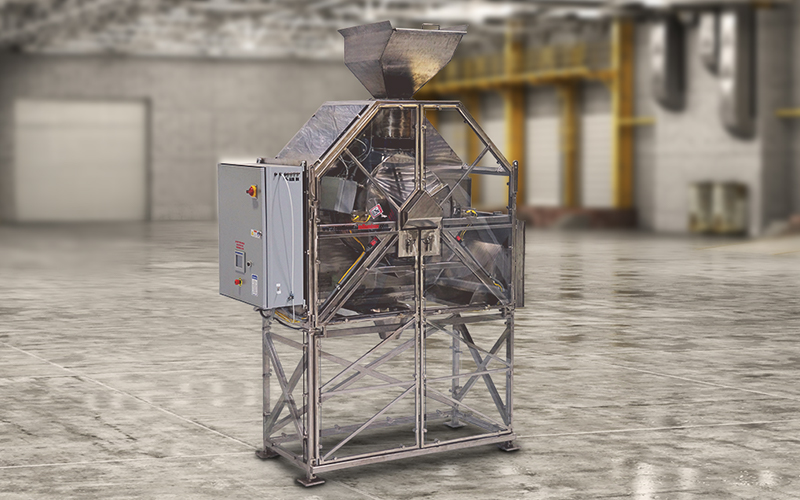

Recommended Rollo-Mixers® for Petrochemical Products

Mk VII

Features & Benefits

- Gentle, Consistent, Uniform Blending

- Homogenize Large lots in 3 minutes

- The World’s largest rotary drum mixer

- Available in 51 sizes from 3.5 to 1,286 cu ft

Mk VIII

Features & Benefits

- High Purity Uniform Mixing in minutes

- Rinse, Clean & Dry in under 15 minutes

- Superior Uniformity & Cleanout to Vee & Cone Blenders

- Available in 9 sizes, from 3.5 to 400 cu ft.

Mk IX

Features & Benefits

- Premier Batch Coater for Slow release fertilizers

- Ability to Heat / Coat & Cool Various Substrates

- Pilot & Production Coaters Available

- Batch to Batch Reproducibility

- Available in 10 sizes, from 3.9 to 297 cu ft

Petrochemical - Media Gallery

Test Your Product

We invite you to run trials with a 5 or 10 cu ft Rollo-Mixer® at our facility in Wisconsin. We will create a private video of the test, exclusively for your review. Viewing windows allow you to watch the blend, and microscope pictures showcase the Rollo-Mixer’s effectiveness. See your petrochemical products uniformly blended or treated with liquids exclusively through "Free-Fall Processing"®

Tell Me MoreCall Us Directly

Call us now to discuss your application. We have worked directly with our customers for over 50 years, and are happy to lend our trusted knowledge to your application. We’re here to help you directly from your initial interest, and testing…. to start up and for the lifespan of your Rollo-Mixer®

Contact Us