Mk X Rollo-Mixer® - Snack & Nut Blender

The Mk X Rollo-Mixer® is a food grade industrial blender for snacks, designed for extremely gentle batch mixing of very friable dry snack food ingredients. The Mk X 50-35/35s can blend dried fruit and very fragile cracker bits, cashews and a variety of nuts uniformly in 80 seconds. The Mk X is Continental’s newest Rollo-Mixer®. It features gentle, uniform blends, complete discharge in seconds and can be rinsed & dried in under 12 minutes. The Mk X Rollo-Mixer® can be made with a fully compliant food grade specification. The rotary drum blender has 35 cu ft of working load volume, as loads vary from 600 to 1,100 lbs depending on product density. Raisins, cranberries, pineapple chunks and other ingredients are loaded into the side of the drum, gently blended and complexly discharged at the six o’clock position, while drum is moving at 4 rpm, and requires only 5 horsepower.

The Mk X is an ideal industrial blender for: mixing snacks and nuts, snack mixes, frozen or dehydrated fruits, vegetable and more.

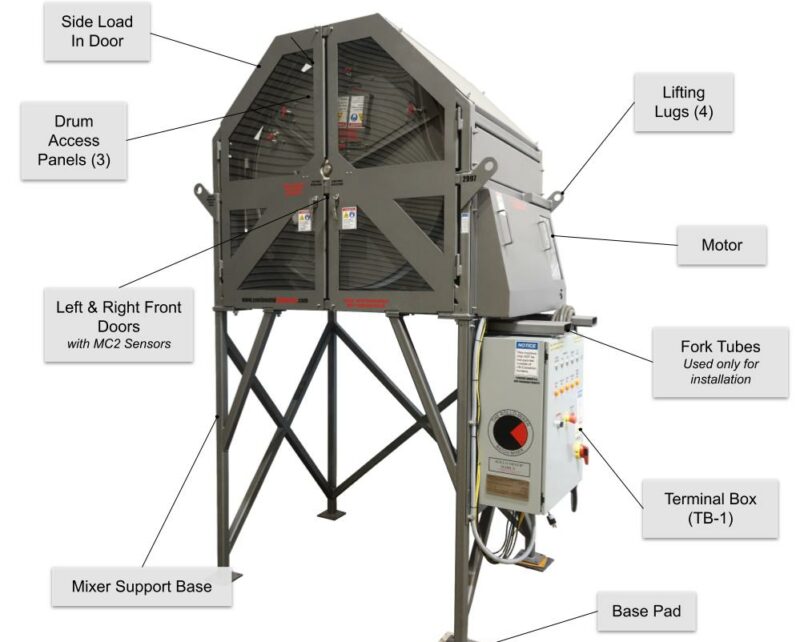

- Mk X Photo Gallery

- Extremely gentle, uniform food grade blending in 80 seconds

- Used for friable snack, nuts and fruit blends

- Food grade package

- Rinse, clean & dry in under 12 minutes

- Available in 11 sizes, from 5 to 386 cu ft

Mk X Applications

Mk X - Media Gallery

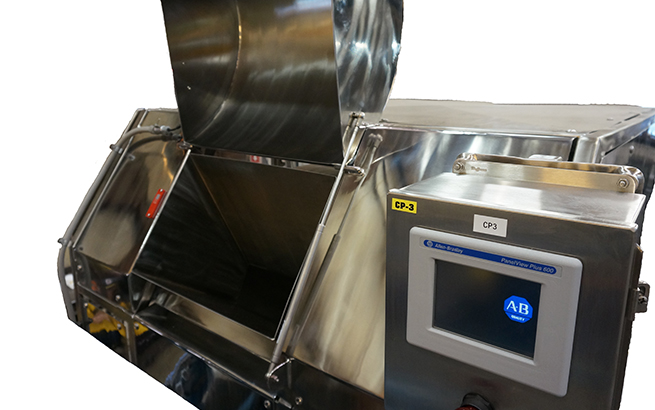

Loading

The Mk X is easily indexed into to the loading position for loading with touch screen controls. A pneumatic gate comes out to allow the operator to very friable products gently into the drum. Usually these nut and fruit snack blends come in bags and boxes. Once loaded, the mixer blends @ 5 rpm as you can watch your products fold into a uniform state in 80 seconds, or less than 10 revolutions.

Discharge

Discharging the Mk X is complete and quick requiring only 2 revolutions. A pneumatically actuated discharged door on the drum opens to allow the entire batch to unload into Gaylord bags / boxes or conveying equipment. The Mk X Rollo-Mixer discharges 100% of the batch and is easily cleaned and sanitized.

Testimonials

“Homogeneous trail mix blends in 80 seconds, rinsed & cleaned in under 10 minutes.”

“Extremely gentle blends for very friable crackers, trail mixes, and fruit blends and more. Our Mk X blends show no damage to cashews, which was our goal”

Additional Information

Materials of Construction Finishes Available

(material contact points)

- 304 L Stainless Steel

- Food Grade Package

- 80 or 150 grit Polished Stainless Steel finish

- Carbon Steel – High Release Finish

- Abrasion Resistant Plate

Safety & Maintenance

- State of the art safety switches

- FDA approved Painted Carbon or Stainless Steel Guarding or Lexan

- Accessible Zirk fittings

- Automatic chain oiler

Standards

- CE

- CSA

- NEMA 12,

- NEMA 4x

- Class II, Div. 1 & 2

Load Volume Calculator

Test Your Product

We invite you to run trials with a 5 or 10 cu ft Rollo-Mixer® at our facility in Wisconsin and watch your products blended or coated. Continental will create a private video of the test, exclusively for your review and help you scale up from a test mixer, to a larger production scale machine.

Tell Me MoreContact Us Directly

Call us now to discuss your application. We have worked directly with our customers for over 50 years, and are happy to lend our trusted knowledge to your application. We’re here to help you directly from your initial interest, and testing…. to start up and for the lifespan of your Rollo-Mixer®

Contact Us