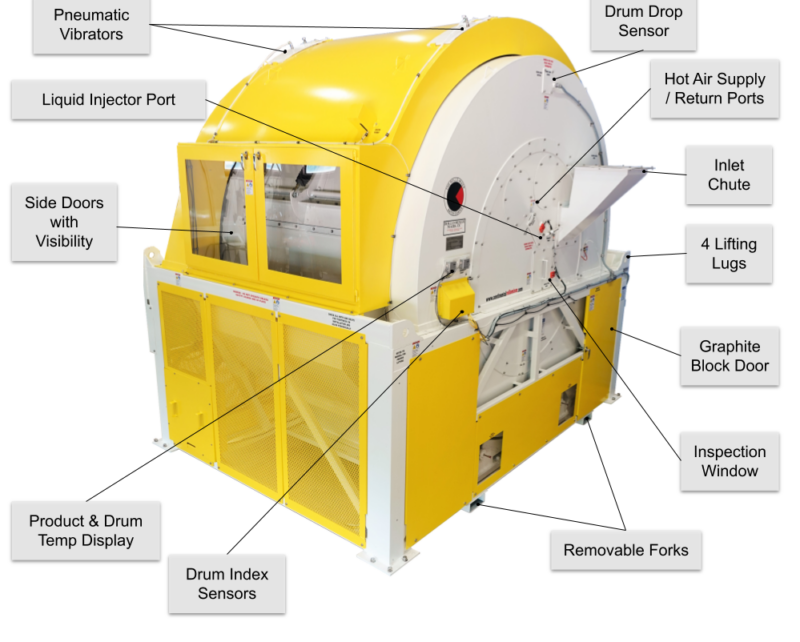

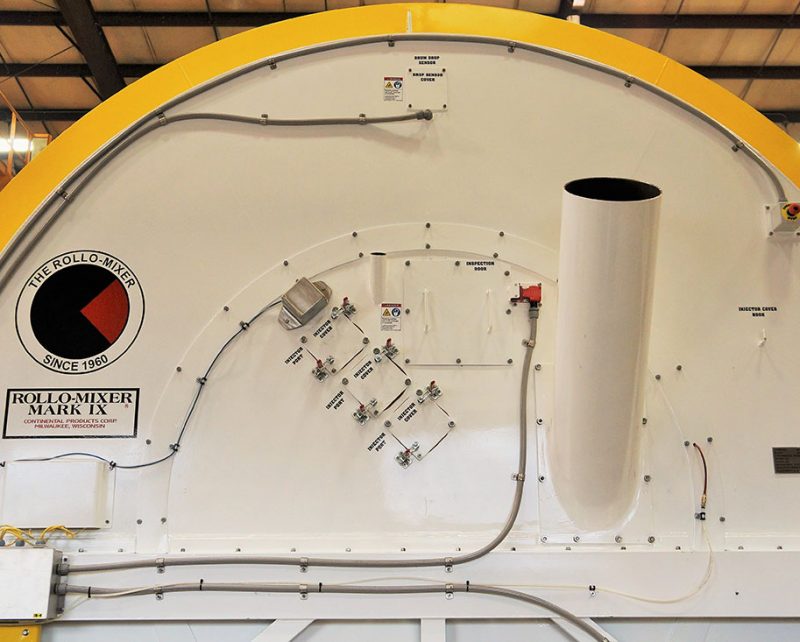

The Mk IX Rollo-Mixer® Batch Coater

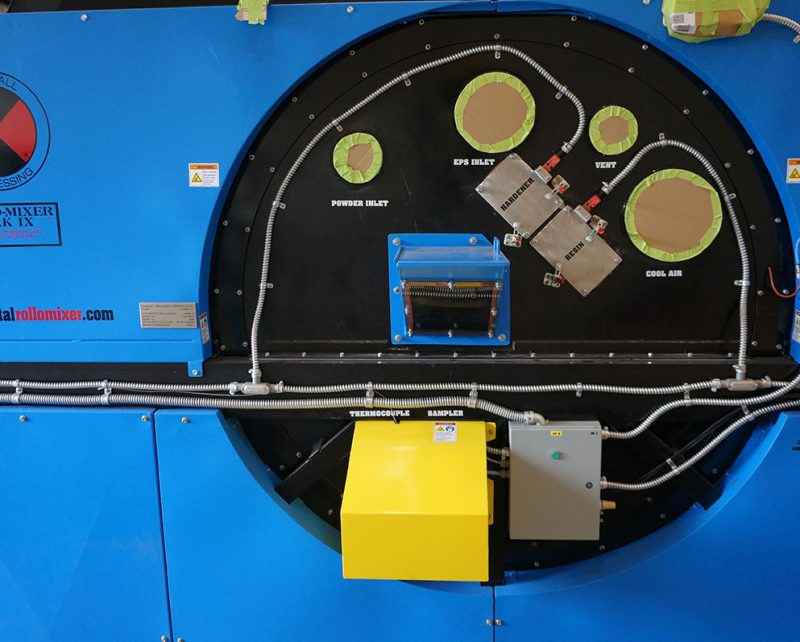

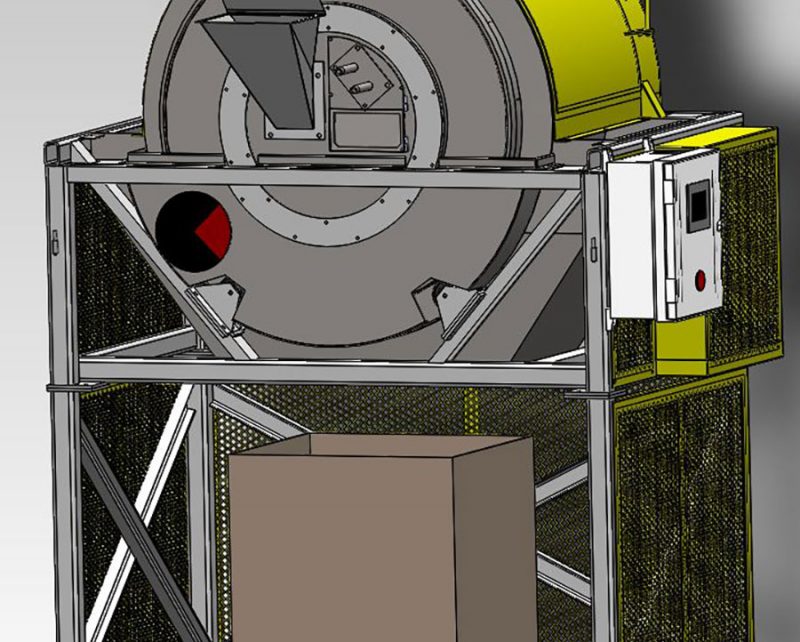

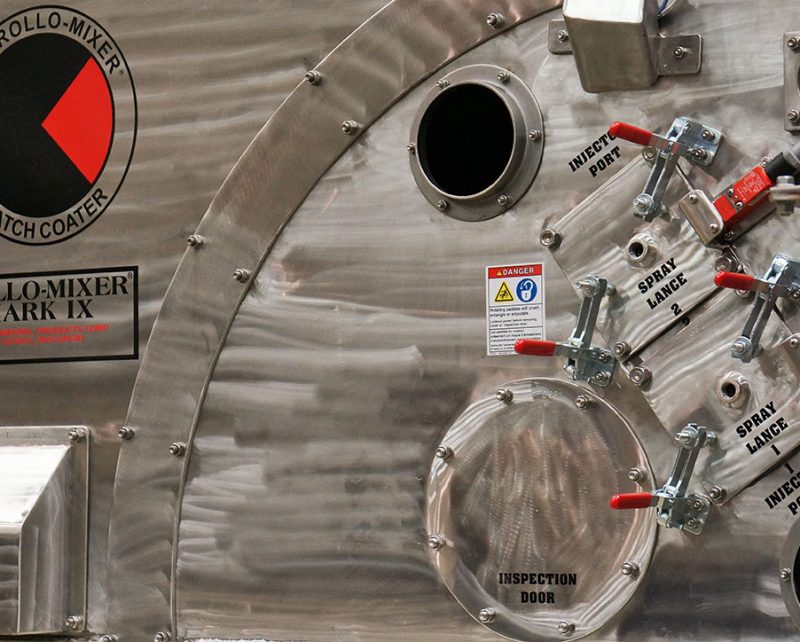

The Mk IX Rollo-Mixer® Batch Coater was originally designed to evenly spray two-part polymer epoxies, resin and hardeners onto a wide range of substrates — from sand to 40 mm spheres. Today’s leading manufacturers of polymer coated slow release fertilizers use the Continental Rollo-Mixer Mk IX Batch Coater for even dispersions of two-part polymers onto a wide variety of fertilizer substrates. Microfilm layers are uniformly applied to the entire surface area of urea, mini urea, and NPK fertilizer products. It has a different coating/mixing action that creates a dynamic rolling bed compared to traditional Rollo-Mixers, which create rivers of material that constantly divide & combine. The Mk IX batch coater is available in both pilot and production size units.

The Mk IX rotary drum coater has a design that is ideal for: controlled release fertilizers, polymer coated fertilizers, biological growth enhancers, micro-layering EPS spheres, agricultural chemicals, pest control products, larvicide and other substrates to be coated with difficult-to-spray liquids.

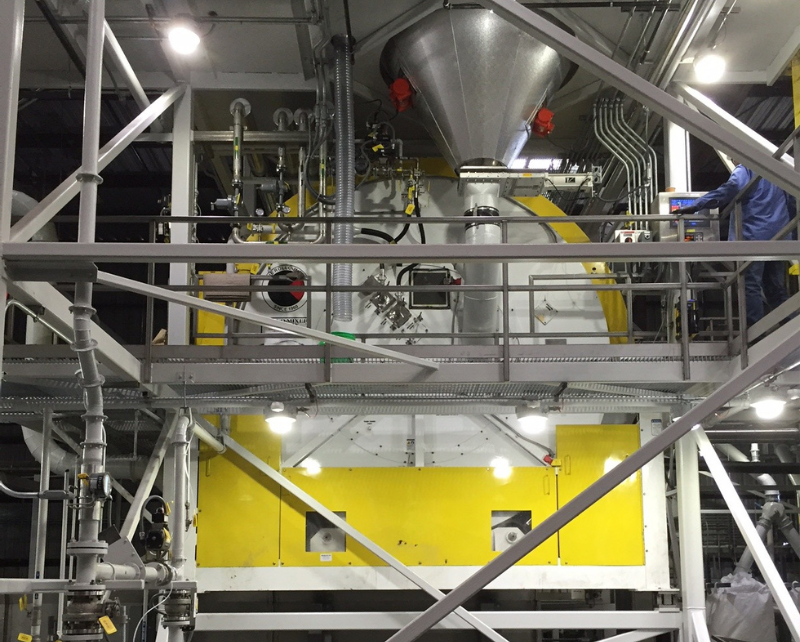

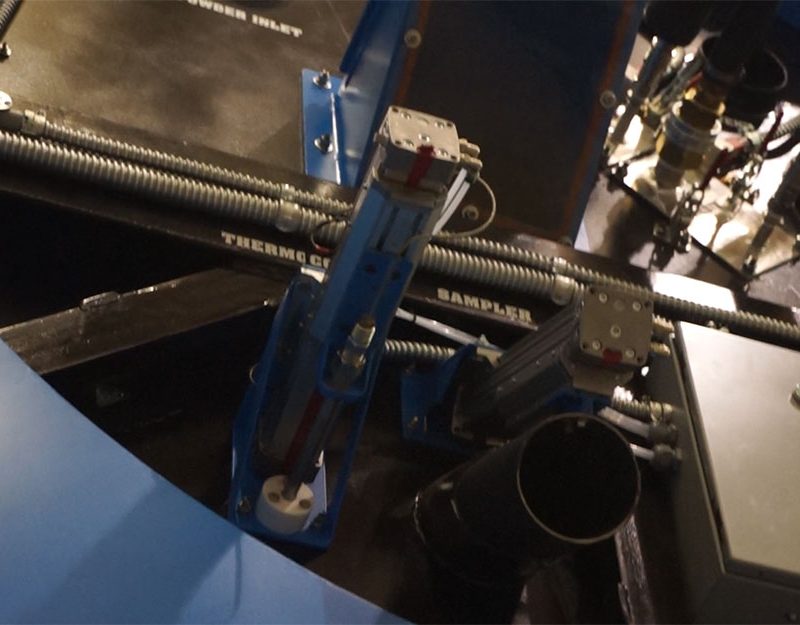

- Mk IX Photos & Videos

- Batch coating

- Available in 10 sizes, from 3.5 to 297 cu ft.

- Premier batch coater for slow release fertilizers

- Ability to heat, coat & cool various substrates

- Pilot & production coaters available

- Batch to batch reproducibility

- Mk IX Features & Accessories

Mk IX Featured Industry Focus

Mk IX - Media Gallery

Mk IX - Features & Accessories

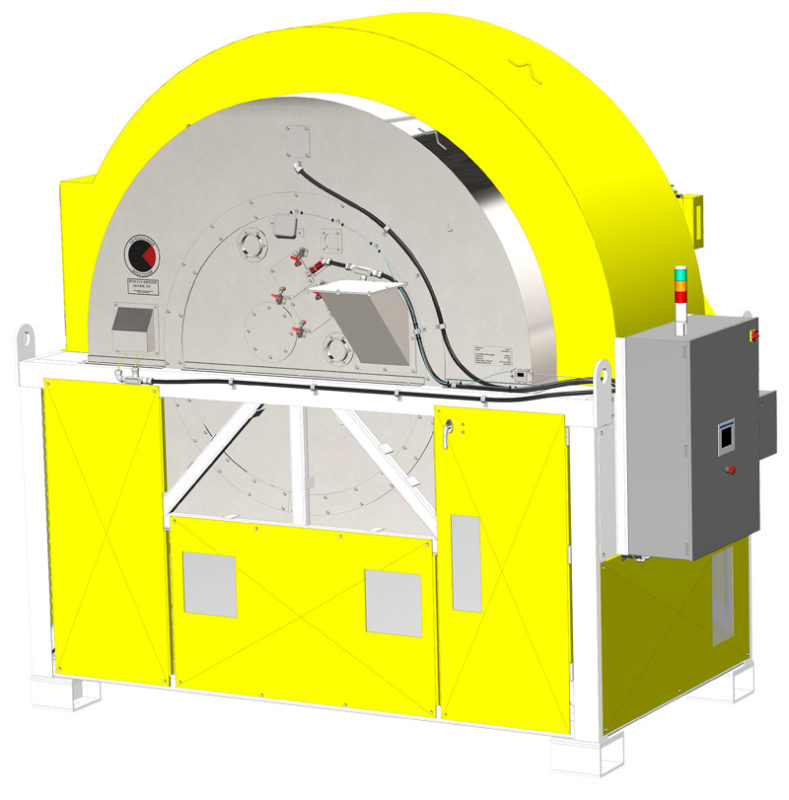

Pilot Batch Coaters

Mk IX Rollo-Mixer pilot batch coaters are currently available in two sizes (3.5 to 11.5 cu ft.) working volume. They are used for formulation development and product innovation in variety of batch coating applications. Continental pilot batch coaters can be equipped with an array of accessories for heating, cooling, coating, and spraying powders or granules. These machines are then scaled up to Mk IX production batch coaters, with a factor of 1:1.

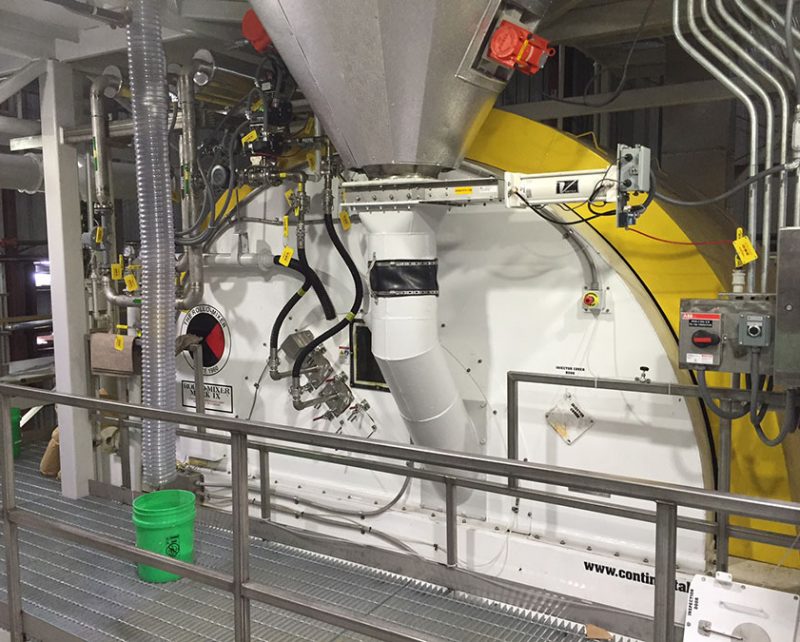

Production Batch Coaters

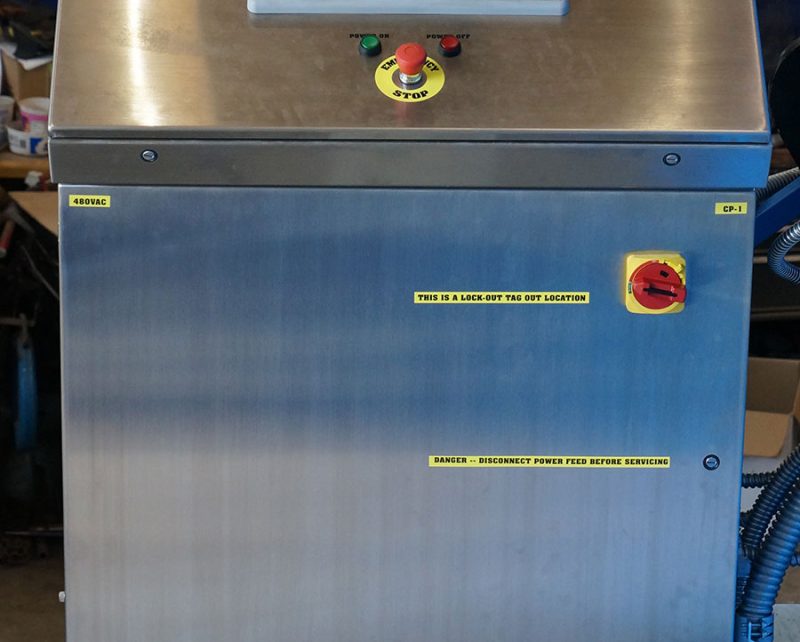

The Mk IX production batch coaters are made in 10 different diameters and range in capacity from 25 to 297 cu ft of working load volume. They are easily adapted into production settings using less space for loading, coating and discharging large production batches. Mk IX Rollo-Mixer batch coaters can be designed to be operated in fully automated or manual batch control modes.

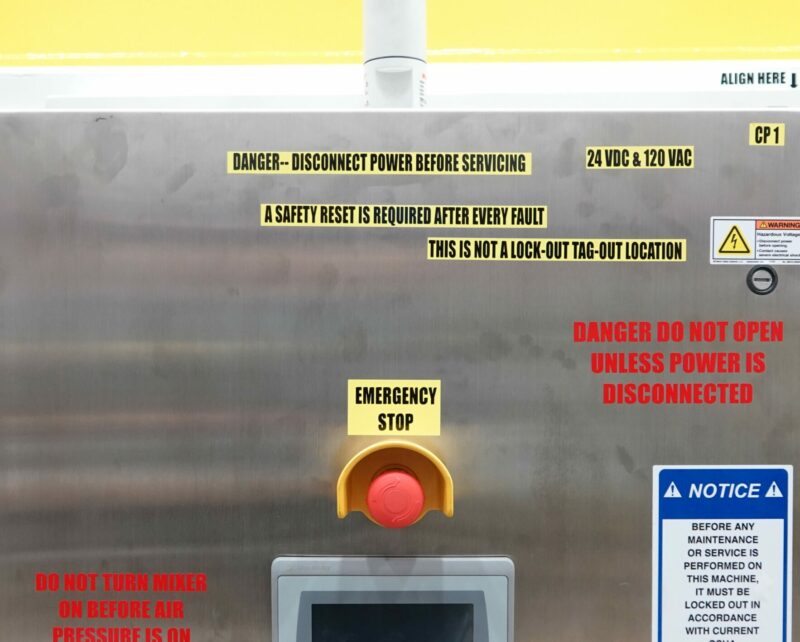

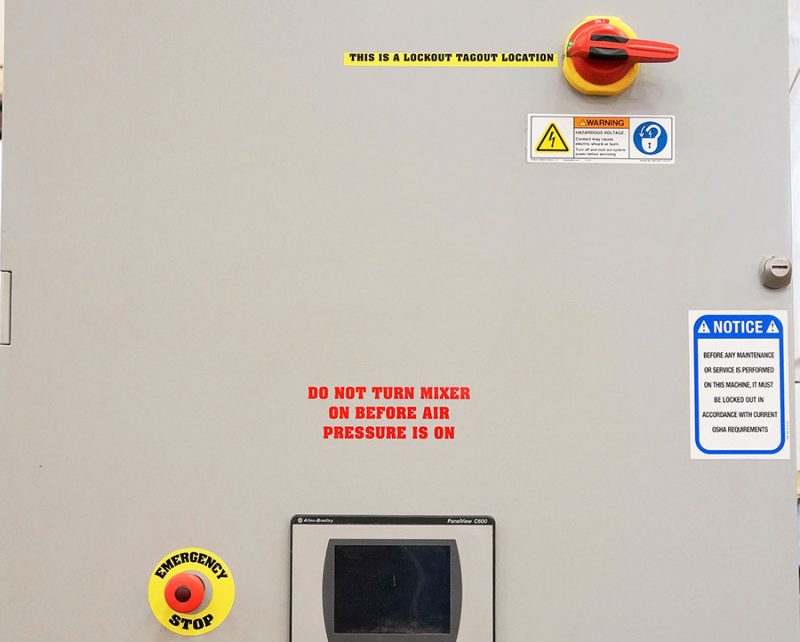

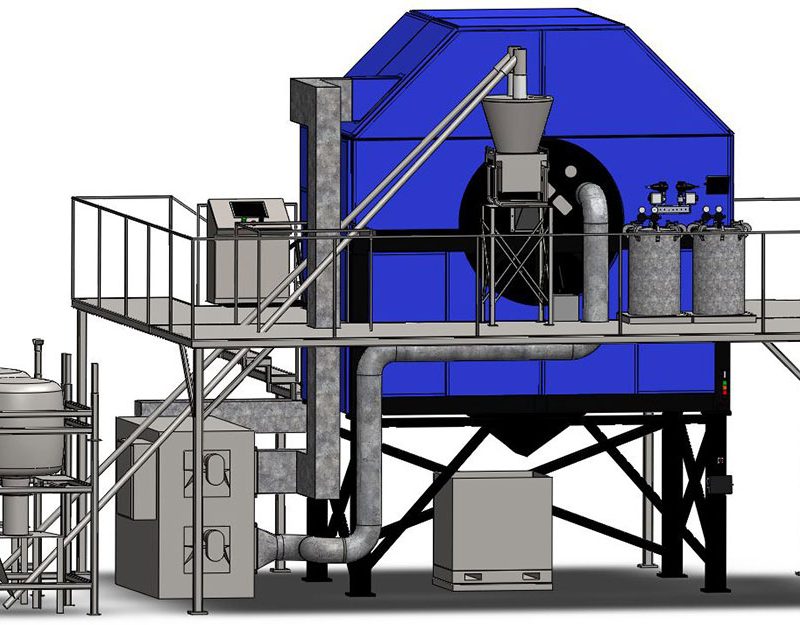

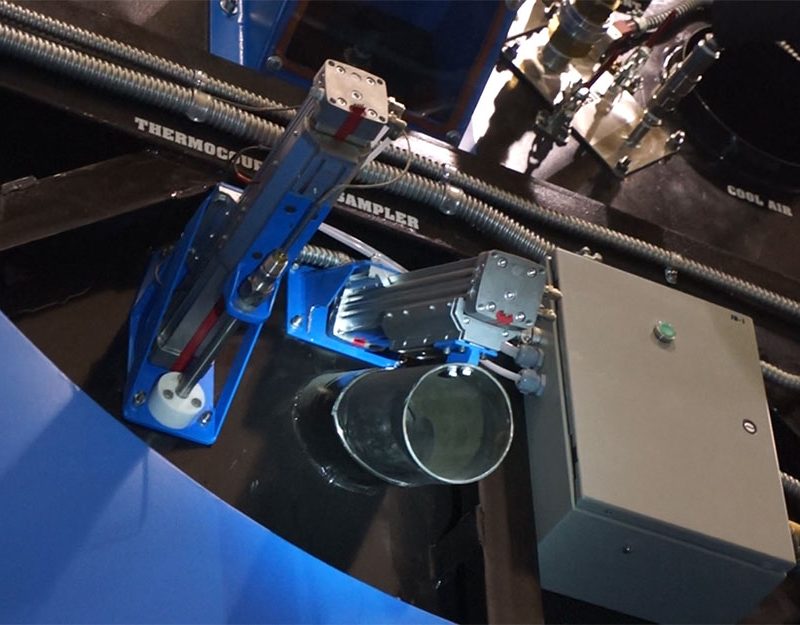

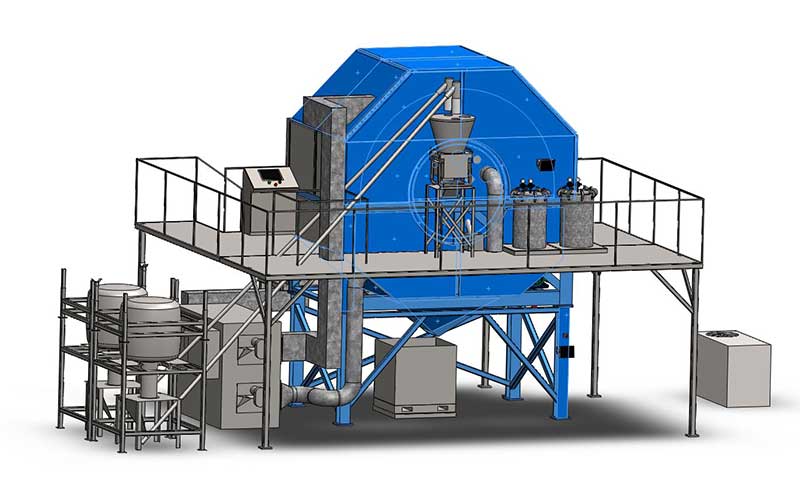

Batch Coating Systems

Mk IX batch coating systems can be fully automated with integrated touch screen control. System features include: heating and cooling with insulated panel enclosures, variable speed drives, bulk powder feeding systems, weighing and liquid spraying systems. Our coating mixer systems create the highest yields and most uniformly coated products — from as small as sand, as common as urea and as large as 40 mm spheres.

Testimonials

With the MK IX, we were able to produce in 16 hours what we had projected to make in 24.

Takes 10 minutes to cure between coats, whether we are making a 150 lb batch in our MK IX pilot coater or 11,500 lb batches in our MK IX Production Coater.

We ran over 270 batch trials on our entire product line and based on the results, R&D has recommended we buy two production 101-333/90s MK IX coaters!

We did not have to clean the inside of the mixer throughout the entire validation process!

Additional Information

Materials of Construction Finishes Available

(material contact points)

- Carbon Steel – High Release Finish

- 304 L Stainless Steel

- 80 or 150 grit Polished finish

- Abrasion Resistant Plate

Safety & Maintenance

- State of the art safety switches

- Painted Carbon or Stainless Steel Guarding

- Accessible Zirk fittings

- Automatic chain oiler

Standards

- CE

- CSA

- NEMA 12,

- NEMA 4x

- Class II, Div. 1 & 2

Mk IX Series & Sizes

Available in 10 sizes from 3.5 ft. to 297 ft. Contact us for dimensional specifications.

- 28 Series (3.5 ft³, 5 ft)

- 31 Series (11.5 ft³, 15 ft³)

- 50 Series (25.4 ft³, 33 ft³)

- 62 Series (55.4 ft³, 75ft³)

- 74 Series (77 ft³, 100ft³, 130 ft³)

- 86 Series (154 ft³, 200 ft³)

- 98 Series (205 ft³, 267 ft³)

- 101 Series (256 ft³, 333 ft³)

- 120 Series (297 ft³ , 386 ft³)

Load Volume Calculator

Test Your Product

We invite you to run trials with our 5 cu ft. Mk IX pilot batch coater at our facility in Wisconsin. Continental will create a private video of the test, exclusively for your review. Viewing windows allow you to watch the blend, and microscope pictures showcase the Rollo-Mixer’s effectiveness. See your substrates coated evenly with, liquids, resins or hardeners.

Tell Me MoreContact Us Directly

Call us now to discuss your application. We have worked directly with our customers for over 50 years, and are happy to lend our trusted knowledge to your application. We’re here to help you directly from your initial interest, and testing…. to start up and for the lifespan of your Rollo-Mixer®

Contact Us