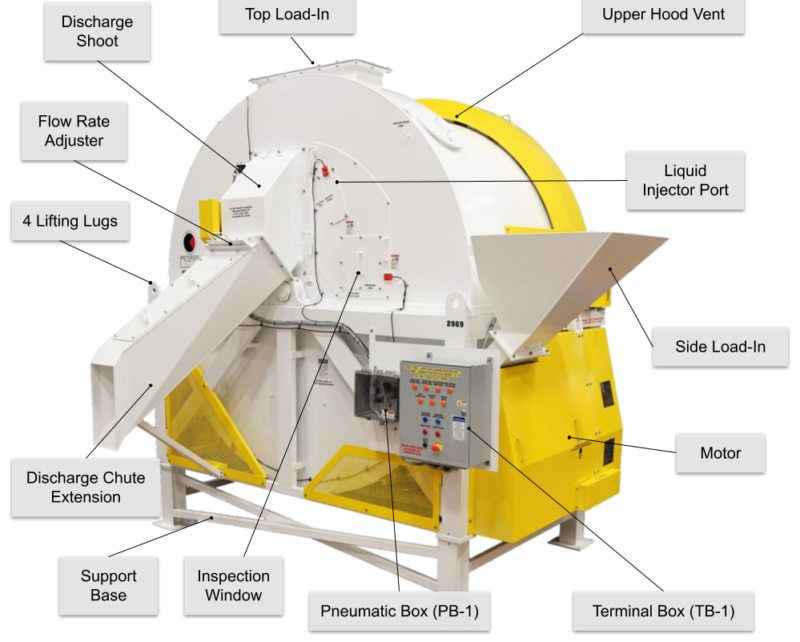

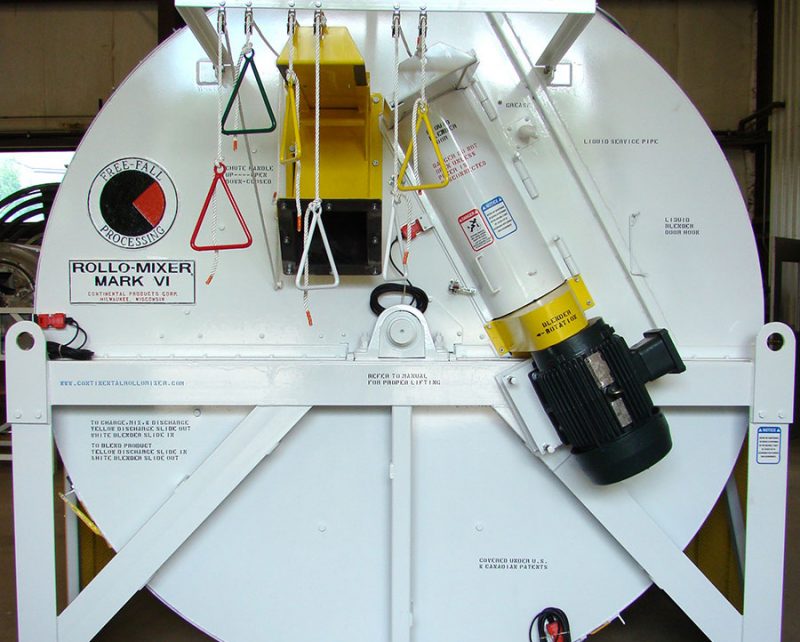

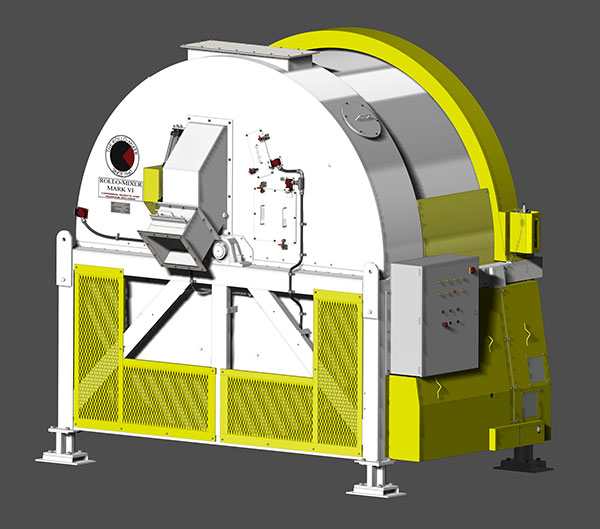

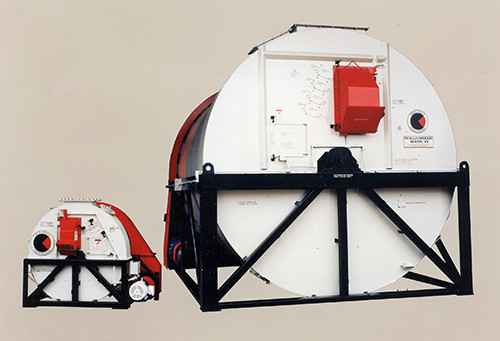

The Mk VI Rollo-Mixer® Batch Mixer

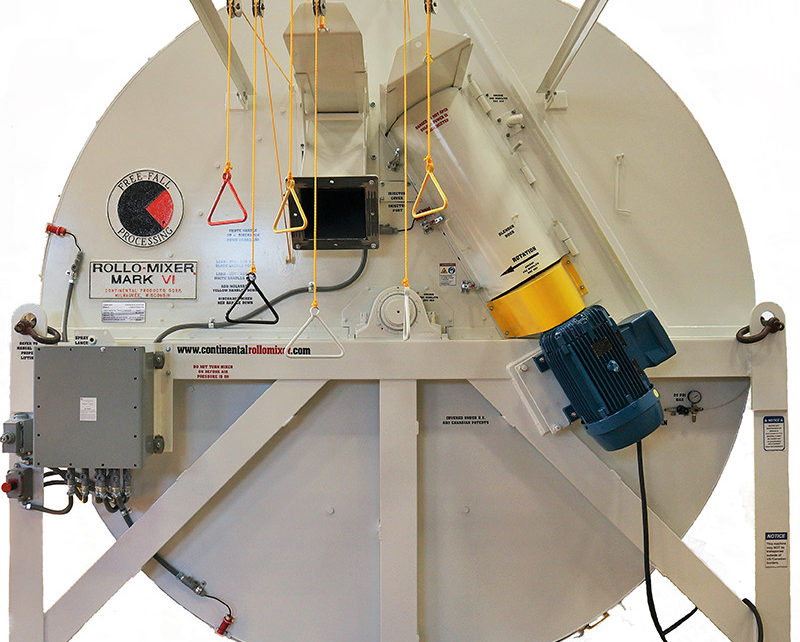

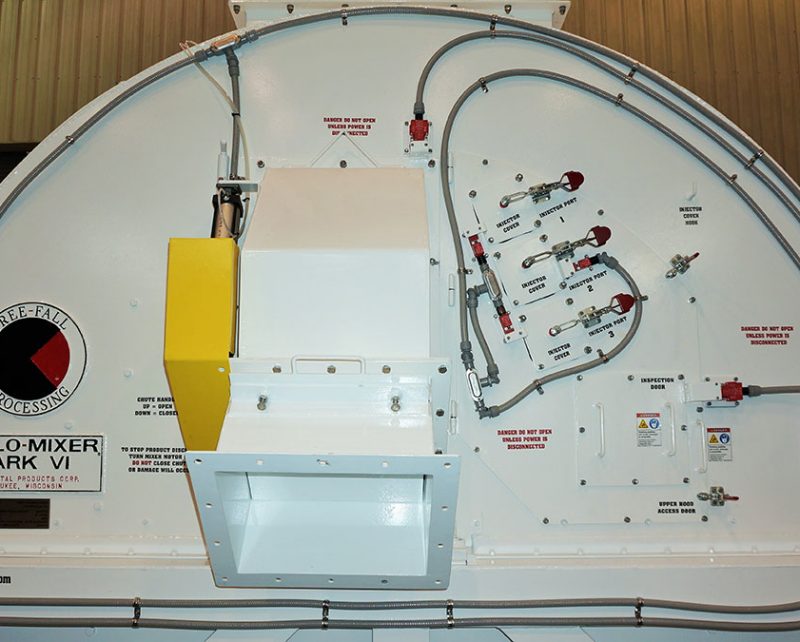

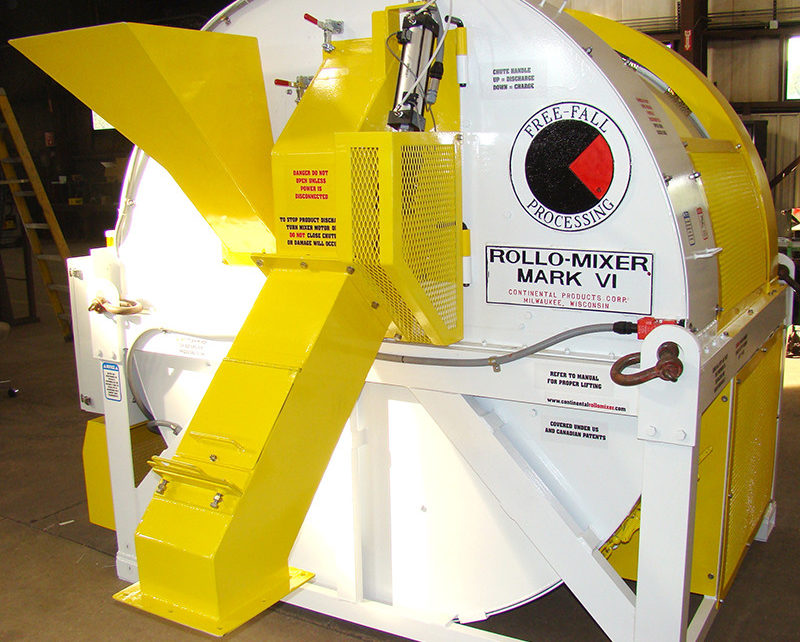

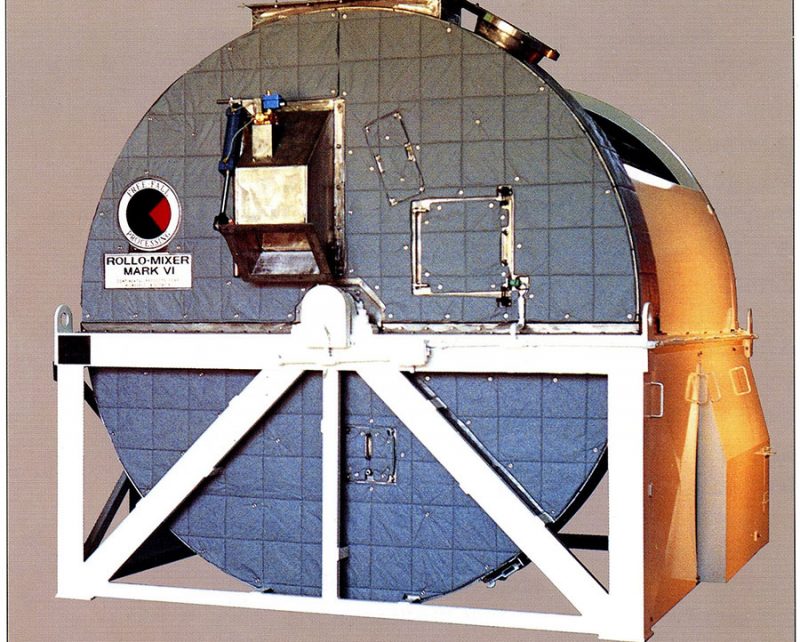

The Mk VI is a globally used batch mixer designed to uniformly blend and evenly coat powders/dry particulates. The Mk VI provides powder blending and coating accuracy in numerous industrial batch mixing, blending and coating applications. The open turbine section offers different loading, access, and venting options.

The Mk VI design is ideal for: Animal Health Products, Calf Milk Replacer, Animal Feed with Molasses, Trace Mineral Pre-Mixes, Specialty Polymers, Treating Powders, Industrial Cleaners, Insulation Products, Coating Kaolin Clays, and Magnesium Oxide Powders

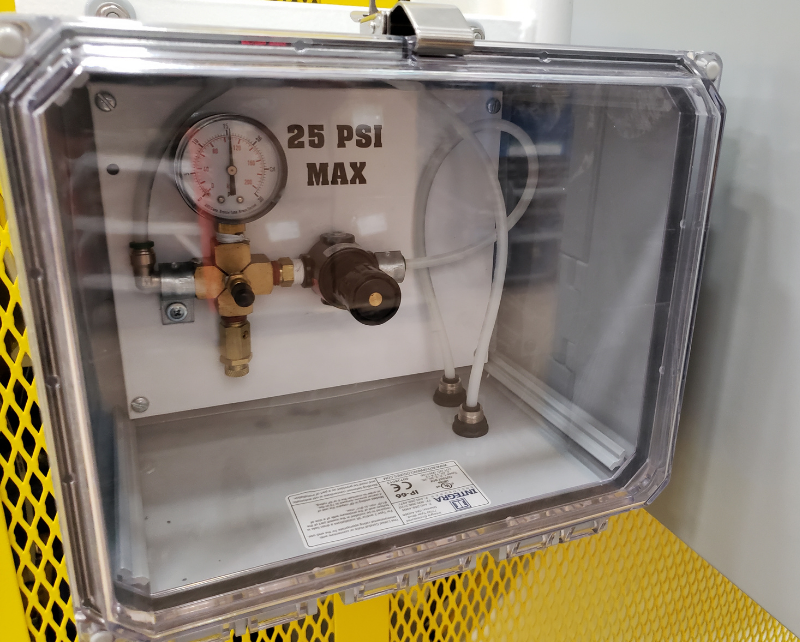

- Built with award-winning liquid addition Free-Fall Processing®

- Known for its proven quality, efficiency and reliability

- Operates with over 25 divisions per revolution

- Results in uniform batch mixing & blending in minutes

- Available in 51 sizes from 3.5 to 1,286 cu ft

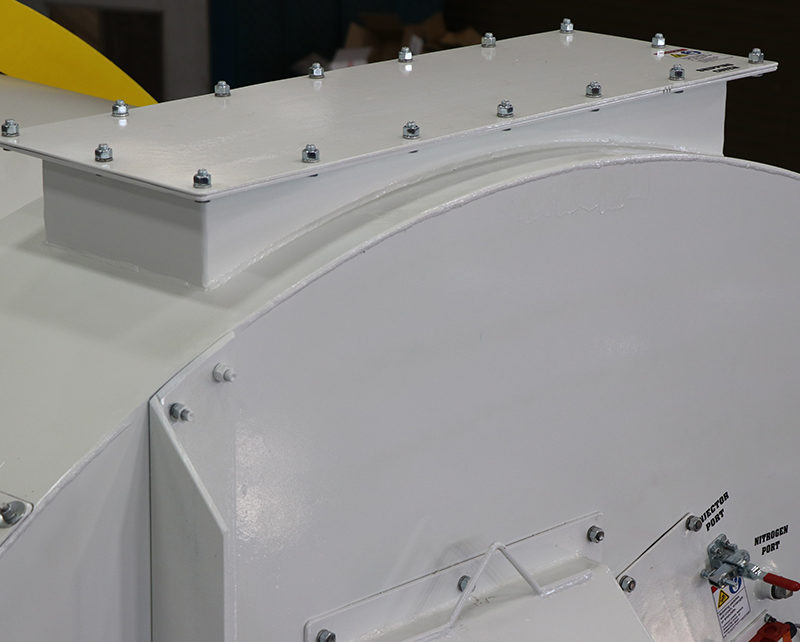

- MK VI Features and Accessories

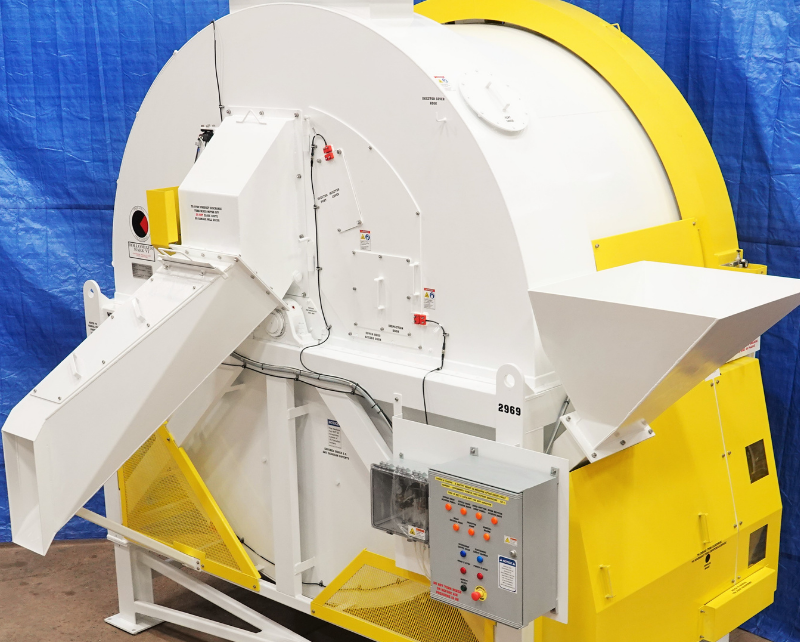

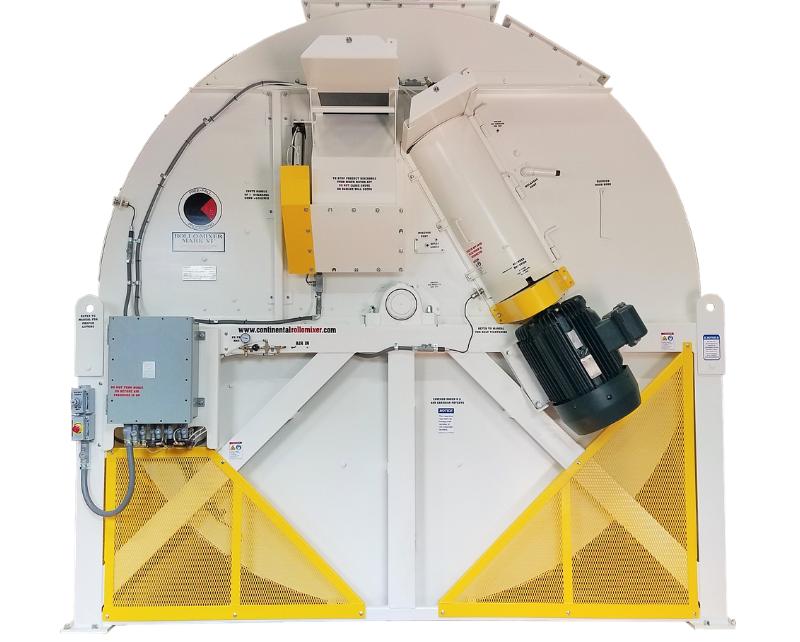

Mk VI - Media Gallery

Mk VI - Features & Accessories

Loading

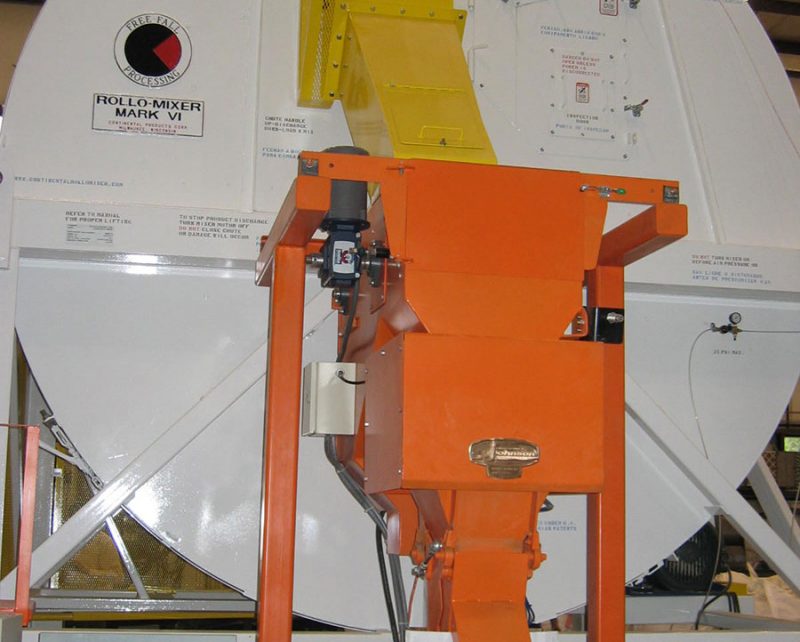

The Mk VI Rollo-Mixer® can be loaded from chutes and hoppers above and on the side of the mixer. The batch mixer is full at shaft center and multiple ingredients can be loaded while it is at rest or in motion. The Rollo-Mixer batch-mixer machine can accommodate multiple methods of loading by gravity from silos, super saks, Gaylord bags, and pneumatically from elevator legs, bags and boxes.

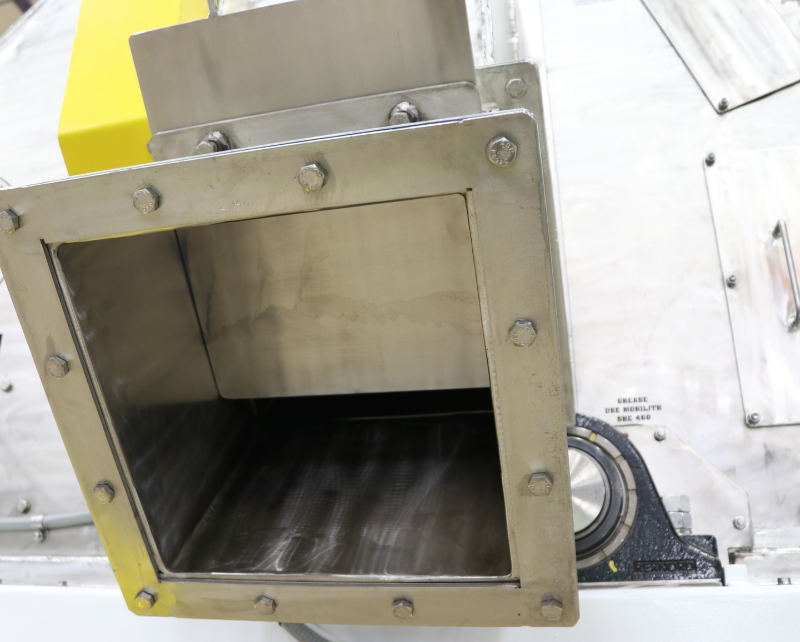

Discharge

While the batch mixer operates, the product is being blended throughout the discharge. Material from the free-falling curtain is diverted out the discharge chute in a steady, unimpeded, uniform stream. Depending on the speed and size of the batch mixer, the product can be discharged up to 2 tons per minute. The Rollo-Mixer® continues running until product discharge is complete.

Testimonials

“We achieve an assay of 50ppm, and are on spec with every batch in our Rollo-Mixer®.”

“Continental Rollo-Mixers, are the finest for mixing radically different density materials or Integrating trace minerals, bar none.”

“We have not had a batch off spec since we put the Rollo-Mixers on line in 1998. We run 24/7/365 and make over 1 million lbs per day.”

Additional Information

Materials of Construction Finishes Available

(material contact points)

- Carbon Steel – High Release Finish

- 304 L Stainless Steel

- 80 or 150 grit Polished finish

- Abrasion Resistant Plate

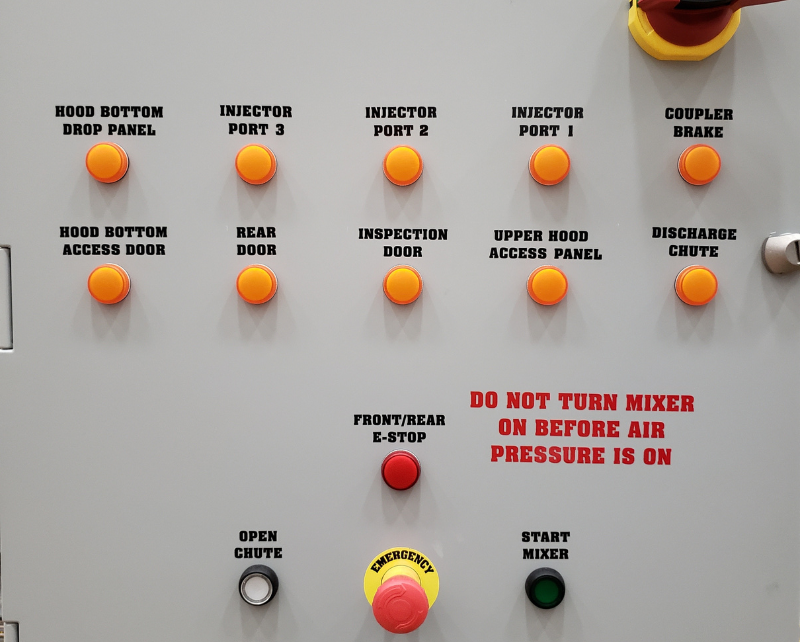

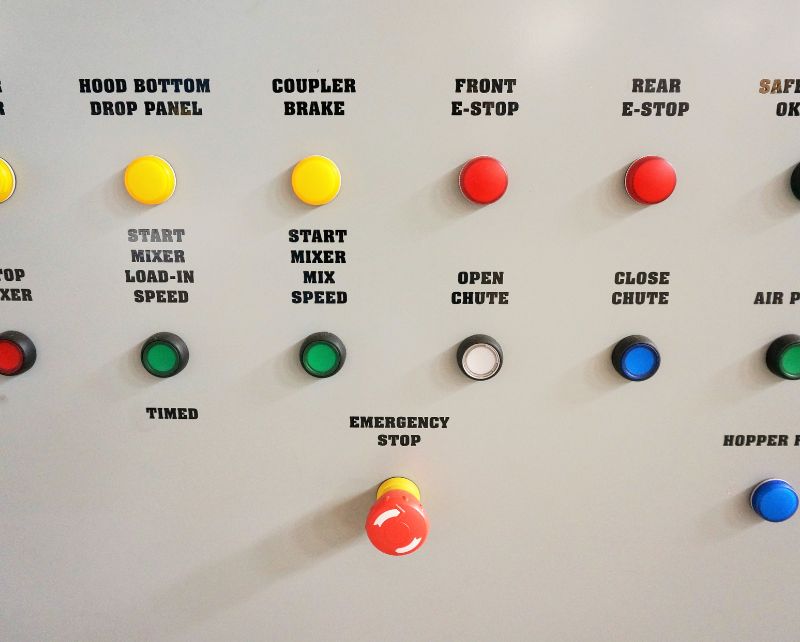

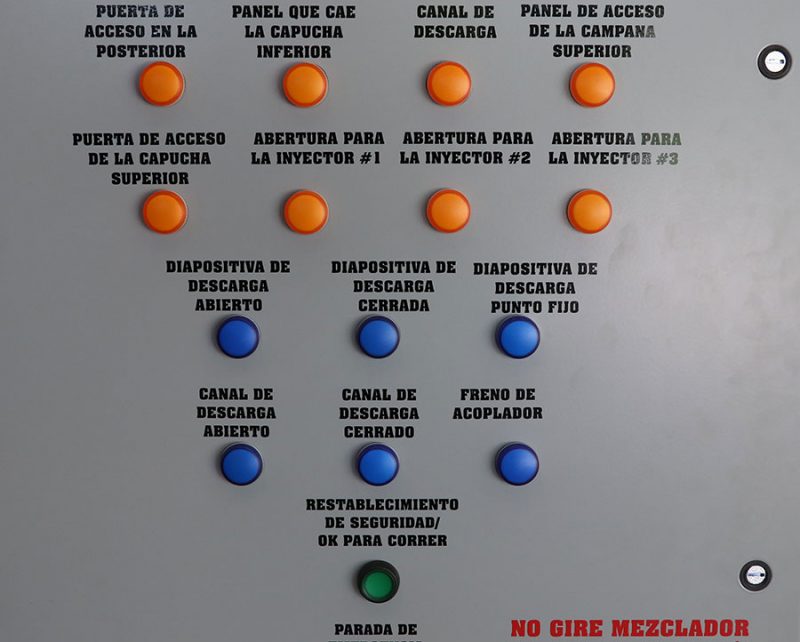

Safety & Maintenance

- State of the art safety switches

- Painted Carbon or Stainless Steel Guarding

- Accessible Zirk fittings

- Automatic chain oiler

Standards

- CE

- CSA

- NEMA 12,

- NEMA 4x

- Class II, Div. 1 & 2

Mk VI Series & Sizes

Available in 51 sizes from 3.5 to 1,286 cu ft. Contact us for dimensional specifications.

- 28 Series (3.5 ft³, 5 ft)

- 31 Series (10 ft³, 15 ft³)

- 50 Series (25 ft³ – 40 ft³)

- 62 Series (40 ft³ – 83 ft³)

- 74 Series (75 ft³ – 172 ft³)

- 86 Series (133 ft³ – 267 ft³)

- 98 Series (200 ft³ – 400 ft³)

- 101 Series (343 ft³ – 629 ft³)

- 120 Series (533 ft³ – 1000 ft³)

- 132 Series (833 ft³ – 1286 ft³)

Load Volume Calculator

Test Your Product

We invite you to our test facility in Wisconsin to run trials with the 10 cu ft Mk VI Rollo-Mixer®. Watch your products be uniformly blended, or treated with liquids in multiple ways exclusively through “Free-Fall Processing”®

Tell Me MoreContact Us Directly

Call us now to discuss your application. We have worked directly with our customers for over 50 years and are happy to lend our trusted knowledge to your application. We’re here to help you from the initial testing to the start-up and the rest of the lifespan of your Rollo-Mixer®

Contact Us