To our customers, suppliers and friends,

On March 25, 2020, at 8 a.m. the State of Wisconsin issued a “Safer at Home” order pursuant to the Governor’s earlier Executive Order declaring a state of emergency. The Order requires all

individuals living in Wisconsin to stay home or at their place of residence, subject to certain exceptions, including the operation of “Essential Businesses and Operations.”

Under the Order, Continental Products is within the scope of Essential Businesses and Operations:

v. Manufacture, distribution, and supply chain for critical products and industries. Manufacturing companies, distributors, and supply chain companies producing and supplying essential products and services in and for industries such as pharmaceutical, technology, biotechnology, healthcare, chemicals and sanitation, waste pickup and disposal, agriculture, food and beverage, transportation, energy, steel and steel products, petroleum and fuel, mining, construction, national defense, communications, and products used by other Essential Governmental Functions and Essential Businesses and Operations.

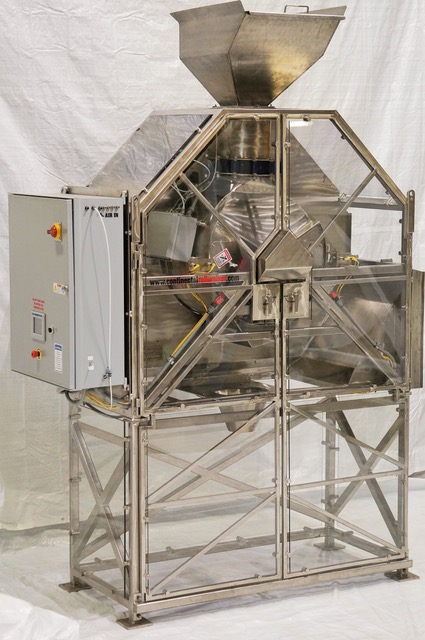

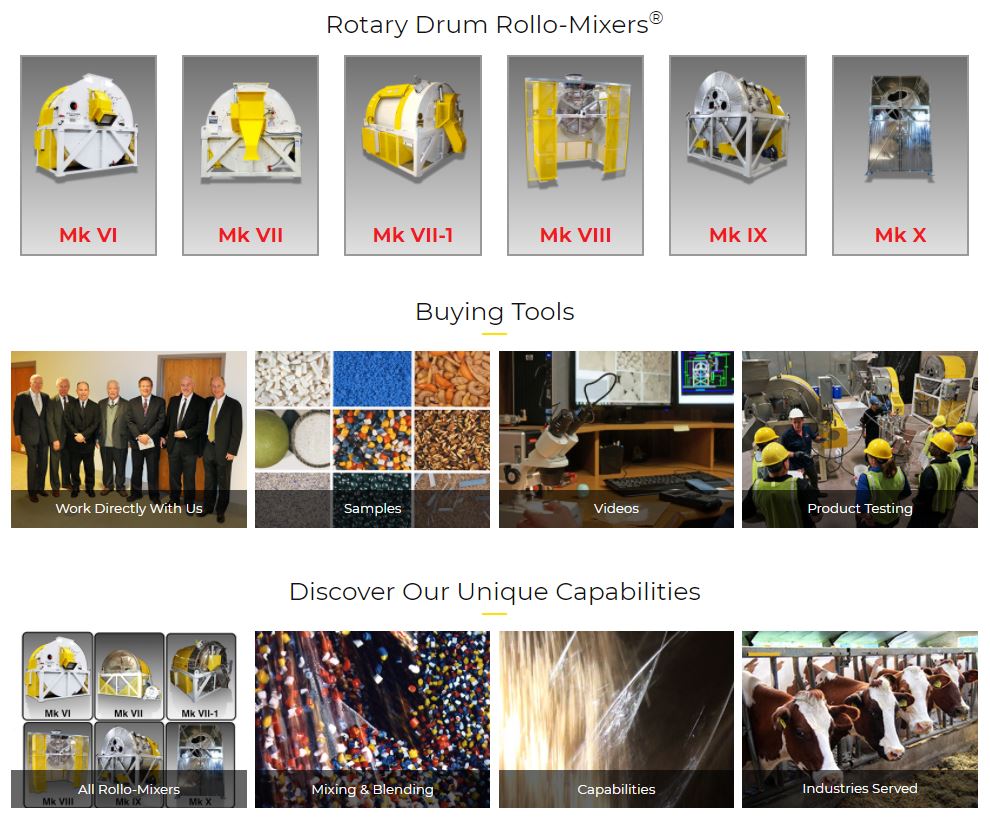

Continental Products Corp. is critical to supplying essential machinery to the agriculture, food and petrochemical industries throughout the US. It is imperative that we stay open for the many customers who rely upon us in this unprecedented time for our country. Continental Products and its employees will continue to operate in accordance with relevant federal and state guidance regarding social distancing and safe workplace practices. Our business hours remain the same and someone is always here to answer your calls. Feel free to contact us anytime via email or our website www.continentalrollomixer.com as well.

Please stay safe and thank you for your continued commitment to our business.

Sincerely,

John Callaghan

President/CEO