Uniform Dry Blending in the Rollo-Mixer®

Uniformity is the hallmark of the Continental Rollo-Mixer®. Since 1960, a main reason our customers have chosen the Rollo-Mixer® is because it is consistently more uniform, in less time, than any other mixer tested. From animal feeds and delicate investment casting blends to nutraceutical powder batches with 84 ingredients, the Rollo-Mixer® provides unrivaled uniform dry blending. Test data shows the Rollo-Mixer® to achieve a more consistent, uniform blends to that of typically known, ribbon and paddle mixers, vee and cone, cement and auger mixers. Rollo-Mixers can be equipped with samplers to verify uniformity. The same dosage, extrusion consistency and ingredient distribution all depend on uniformity. We have customers that blend batches that cost over $300,000 dollars per batch. They rely on the Rollo-Mixer® to provide them with nothing but uniformity, where it is absolutely critical.

Uniform Dry Blending - Media Gallery

Recommended Rollo-Mixers ® for Uniform Dry Blending

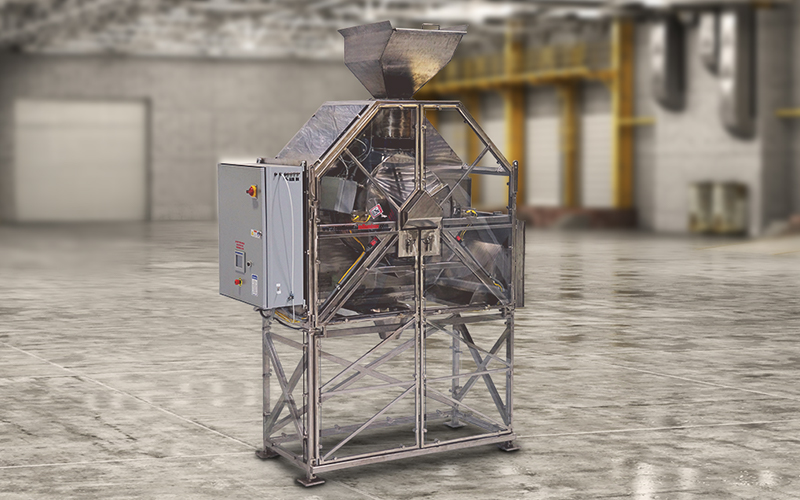

Mk VI

Features & Benefits

- Uniform Batch Mixing & Blending in under 3 minutes

- Award winning liquid addition Free-Fall Processing®

- Available in 51 sizes from 3.5 to 1,286 cu ft

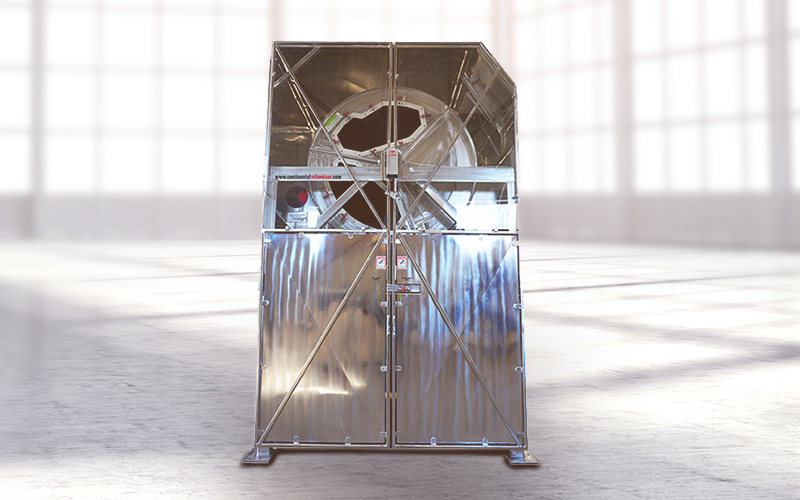

Mk VII

Features & Benefits

- Gentle, Consistent, Uniform Blending

- Homogenize Large lots in 3 minutes

- The World’s largest rotary drum mixer

- Available in 51 sizes from 3.5 to 1,286 cu ft

Mk VII-1

Features & Benefits

- Uniform Mixing and Blending in under 3 minutes

- Precise liquid addition – featuring Free-Fall Processing®

- Versatile Solids Processor – available with heating & cooling capabilities.

- Available in in 51 sizes from 3.5 to 1,286 cu ft

Mk VIII

Features & Benefits

- High Purity Uniform Mixing in minutes

- Rinse, Clean & Dry in under 15 minutes

- Superior Uniformity & Cleanout to Vee & Cone Blenders

- Available in 9 sizes, from 3.5 to 400 cu ft.

Mk X

Features & Benefits

- Extremely Gentle, Food Grade Blending

- Uniformity in 80 seconds

- Used for friable snack, nuts and fruit blends

- Rinse, Clean & Dry in under 12 minutes

- Available in 11 sizes from 5 to 386 cu ft

A World Leader in Rotary Drum Mixing, Blending, and Coating Technology

We’ve been leading the way in innovative solutions for mixing, blending and coating since 1960. We carry a series of premier rotary drum batch mixers which deliver superior results across many industries. Working directly with our customers, we are with them every step of the way to make their products better than ever before.

Uniform Mixing

Gentle Blending

Award winning coating technology

Batch to Batch consistency

Improve Quality of Finished Products

Increase Production

Test Your Product

We invite you to run trials with a 5 or 10 cu ft Rollo-Mixer® at our facility in Wisconsin. We will create a private video of the test, exclusively for your review. Viewing windows allow you to watch the blend, and microscope pictures showcase the Rollo-Mixer’s effectiveness. See your dry blends uniformly mixed in the Rollo-Mixer®

Tell Me MoreCall Us Directly

Call us now to discuss your application. We have worked directly with our customers for over 50 years, and are happy to lend our trusted knowledge to your application. We’re here to help you directly from your initial interest, and testing…. to start up and for the lifespan of your Rollo-Mixer®

Contact Us