Paddle, Plow or Ribbon Mixers

Ribbon, Paddle, or Plow Mixers

- Difficult to mix dissimilar particle sizes and densities uniformly.

- Difficult to mix low inclusions additives uniformly.

- Reel rotates approximately 30 rpm through the batch, inducing friction and fracture to the particles. Machinery induced wiping action moves product back and forth.

- Draws high energy consumption due to large horsepower requirement.

- Difficult to start and stop under full load.

- Liquids are unevenly distributed onto the product.

- Wear to the tub or reel effects mixing efficiency.

- Requires a minimum 2/3 reel height to mix.

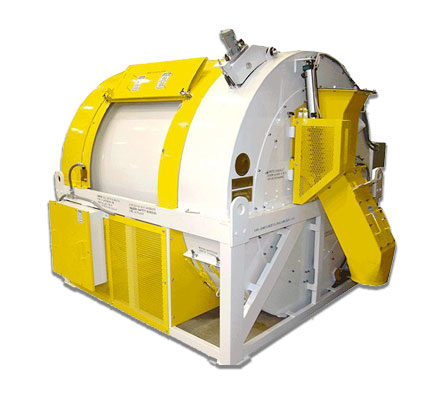

Continental Rollo-Mixer ®

- Uniformly blends dissimilar particle sizes and densities as well as low inclusion additives.

- Drum rotates at approximately 3 rpm without damaging particles in the batch. Rivers of material flow by gravity in all planes.

- Requires 80% less energy to blend the same size batch. Substantial energy savings and rebates.

- Designed to start and stop under a full load.

- Liquid Additives are uniformly applied onto all the particle surface area with Award Winning “Free Fall processing” ®.

- No mechanical tolerances to effect mixing efficiency.

- Able to blend any size batch from zero to rated load volume uniformly.

- Available in 51 sizes from 3.5 to 1,286 cu ft

Test Your Product

We invite you to our test facility in Wisconsin to run trials with the 10 cu ft Mk VI Rollo-Mixer®. Watch your products be uniformly blended, or treated with liquids in multiple ways exclusively through “Free-Fall Processing”®

Tell Me MoreCall Us Directly

Call us now to discuss your application. We have worked directly with our customers for over 50 years, and are happy to lend our trusted knowledge to your application. We’re here to help you directly from your initial interest, and testing…. to start up and for the lifespan of your Rollo-Mixer®

Contact Us